Chemists from University Utrecht along with Delft University of Technology and Dow Benelux have developed a new catalyst that enables production of various petroleum-free products, including paint, medicines and plastics.

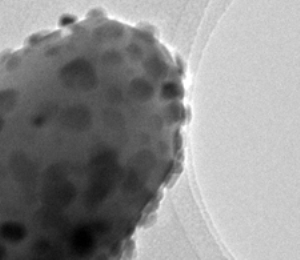

The catalyst viewed through an electron microscope. The tiny iron spheres (dark areas) measure only about 20 nanometres in diameter. Gas generated from biomass is converted into substances currently produced from petroleum.

The catalyst viewed through an electron microscope. The tiny iron spheres (dark areas) measure only about 20 nanometres in diameter. Gas generated from biomass is converted into substances currently produced from petroleum.

Currently, most chemical products that range from pharmaceuticals to paint and plastics are made from petroleum. However, the fabrication of products using previous technologies involved several steps. Hence, the technology has not been efficient and economical for large-scale applications. With the use of a new catalyst, it is currently possible to create components that can be utilized to produce plastics and other products in a one-step process. The products are the same as those produced from petroleum but the only difference is that they are made from pruning waste or biomass. The catalyst is made of iron nanoparticles measuring about 20 nm in diameter.

Hirsa Torres, PhD student at University Utrecht, has produced and stabilized the tiny iron spheres, which makes the catalyst highly durable and efficient enough to convert biogas into useful materials.

One major benefit offered by the new method is the use of sustainable raw materials such as pruning waste, plant stalks and branches. Krijn de Jong, University professor, stated that the use of sustainable materials is a good alternative for the industry due to forthcoming oil shortage. Researchers expect that the first products made from the catalyst will be introduced shortly.