Nuremberg, Germany-based Siemens Industry Automation Division has delivered another Zimpro wet air oxidation (WAO) system to Sinopec Yangzi Petrochemical, a wholly-owned subsidiary of China Petroleum & Chemical.

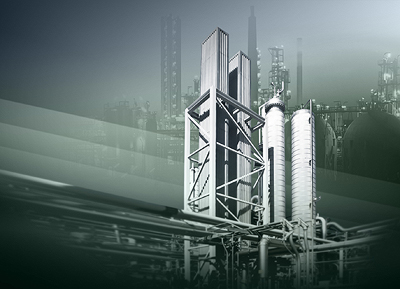

Zimpro wet air oxidation (WAO) system

Zimpro wet air oxidation (WAO) system

The system will be used to treat wastewater or effluents at Sinopec‘s facility located near the Yangzi River, Jiangsu Province, China. In addition, Siemens’ Zimpro system will break down organic contaminants like phenols into either biodegradable organics or water and carbon dioxide.

A total of seven WAO systems have been deployed at various Sinopec’s facilities. The systems will be utilized to process spent sulfidic caustic wastewater resulting from the manufacturing of petrochemicals. They produce a biodegradable waste stream, which can be released into conventional biological sewage treatment. Thus, the Zimpro WAO systems prevent generation of stinking sulfide pollutants such as mercaptides and sulfides, and will help make the petrochemical production process more eco-friendly.

The Siemens’ technology deployed at the Yangzi facility is expected to commence operation by the end of 2012 and is estimated to treat about 17.6 gpm of effluents. Wet oxidation is a process of oxidizing soluble or floating matters in an aqueous environment with the use of oxygen (O2). The process is known as wet air oxidation (WAO), if air is utilized as the source of O2. Sinopec’s Yangzi facility comprises a petrochemical plant and a refinery. The Sinopec project signifies the installation of the ninth Siemens’ Zimpro system in China to treat spent caustic waste.