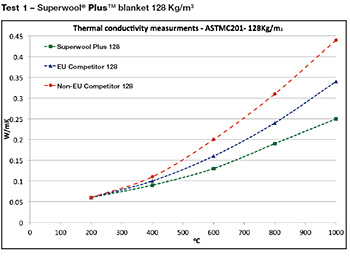

Morgan Thermal Ceramics' Superwool Plus high temperature thermal insulation has been independently tested and is proven to have a thermal conductivity up to 40% lower than comparable insulation products at 1000°C.

As such, it is confirmed as being more energy efficient than its alternatives, allowing users to make significant energy cost savings and reduce their carbon footprint.

Performance of Morgan Thermal Ceramics' Superwool Plus blanket 128kg/m3.

Performance of Morgan Thermal Ceramics' Superwool Plus blanket 128kg/m3.

Superwool Plus blankets of density 128 kg/m3, 96 kg/m3, 80 kg/m3, were tested against competitor blankets of density 128 kg/m3 and 96 kg/m3 by a French laboratory in accordance with the ASTM C201 - 93(2009) standard test method for thermal conductivity of refractories.

Results show that Superwool Plus insulation has outstanding thermal conductivity, with all the Superwool Plus blankets having lower thermal conductivities than competitor products.

Consequently, customers can 'drop a density' of insulation and achieve the same high insulation performance when compared to competitor products. The lighter Superwool Plus 96 kg/m3 blanket can be used in place of a competitors' 128 kg/m3 blanket, or a Superwool Plus 80 kg/m3 blanket in place of a competitors' 96 kg/m3 blanket, enabling users to make significant weight and cost savings.

Superwool Plus fibre is simple to install and delivers excellent insulation in high temperature environments with a classification temperature of 1200°C. It has high tensile strength with good handling ability and does not tear easily.

Superwool Plus insulation also has health and safety benefits compared to traditional refractory ceramic fibres (RCF) as it is a low bio-persistent fibre insulation and is exonerated from the carcinogen classification in the EU under the terms of Nota Q of Directive 67/548/EEC.

"Third party testing of our high performance insulation provides invaluable data and proves that our Superwool Plus blankets really do have the lowest thermal conductivity," says Ron Wainwright, Technical Director, Morgan Thermal Ceramics. "Customers can now be assured of a high quality thermal insulation which provides exceptional energy efficiency and enables them to make associated energy cost savings."

"What's more, the independent data backs up our own thermal conductivity values and validates the accuracy of our testing and data sheets. At Morgan Thermal Ceramics we have a long history and experience in thermal conductivity measurement and as such, our customers can be confident in our values being correct and genuinely representative."

The insulation is ideal for high temperature applications in the power and chemical processing industries. For example, it is used in various insulation applications throughout heat recovery steam generators. In addition, Superwool Plus fibre is used to produce Morgan Thermal Ceramics' world renowned fire protection blanket FireMaster Marine Plus blanket, enabling lighter, more flexible and simple to install fire protection systems to be adopted.

It is also used in high temperature processing applications to line kilns and furnaces in many industries including ceramics, iron & steel and aluminium, as well as insulation in automotive exhaust heat shields and domestic ovens.