A team of researchers from the Purdue University has developed a coating technique using nanotechnology to recapture waste energy from cars, power plants and factories.

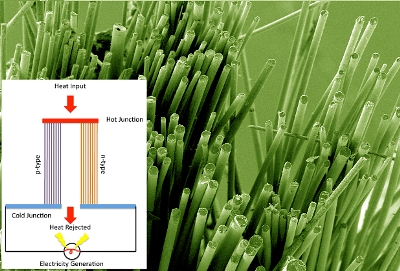

This image shows glass fibers coated with a thermoelectric material that generates electrical current when exposed to heat. The technology might be used to harvest energy from hot pipes or engine components, possibly representing a way to recover energy wasted in factories, power plants and cars. (Purdue University photo/Scott W. Finefrock)

This image shows glass fibers coated with a thermoelectric material that generates electrical current when exposed to heat. The technology might be used to harvest energy from hot pipes or engine components, possibly representing a way to recover energy wasted in factories, power plants and cars. (Purdue University photo/Scott W. Finefrock)

The research team has developed a thermoelectric material. When this thermoelectric material is coated over glass fibers and exposed to heat, it generates electrical current by making electrons to flow towards the cooler side. The coating technique involves the dipping of the glass fibers in a lead telluride nanocrystal solution followed by an annealing process to make the crystals fuse together.

Traditional thermoelectric devices require large amounts of high-performance thermoelectric materials, which have a tendency to break. The nanocrystal-coated fibers are flexible, thus they can be conformed to the irregular shapes of exhaust pipes and engines to recover most of the wasted energy. Moreover, they use a fraction of the thermoelectric material.

The nanocrystal-coated fibers may be utilized as a solid-state cooling technique that eliminates the use of chemical refrigerants and compressors. They may also be used to fabricate cooling garments. According to the team, the new technique is scalable to industrial processes.

The research team has demonstrated that the new thermoelectric material has a high thermoelectric efficiency, which is measured in terms of ZT. The nanocrystals are a key element because their interfaces suppress the crystal lattice structure vibration, which in turn decreases thermal conductivity. They may demonstrate ‘quantum confinement’ where the tiny structures act virtually like individual atoms. The ZT number can be increased by this confinement.

Yue Wu, one of the researchers, stated that the team has created a single parameter termed as the efficiency ratio by studying the abundance, cost, performance and toxicity of the material. The researchers have filed a US patent application for the fiber coating technique.

The research team’s next step is to enhance efficiency through higher temperature annealing. The team is also finding ways to eliminate the annealing process completely, which may enable to coat polymer fibers rather than glass fibers. Since the thermoelectric material has a tendency to break when they are twisted at sharp angles, the team may also work on improving the resilience of the material by providing the glass fibers a polymer coating. The team is also trying to use other materials in place of toxic tellurium and lead.