Researchers at Purdue University have discovered sinuous flow deformation in metals, and an astonishingly simple method to suppress this deformation. This discovery could help advance manufacturing by increasing the efficiency of machining, and by reducing the energy and force required for metal processing.

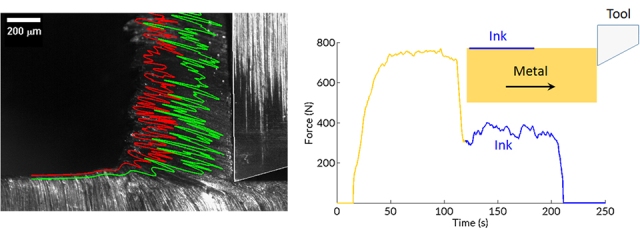

This image, at left, shows a previously unknown type of metal deformation – sinuous flow -in which metal is deformed into folds while it is being cut. New research findings, in graph at right, reveal the cutting force can be reduced 50 percent simply by painting metal with a standard marking ink, suggesting that not only can energy consumption be reduced by 50 percent but also that machining metals can be achieved faster and more efficiently and with improved surface quality. (Purdue University image/ Ho Yeung and Koushik Viswanathan)

This image, at left, shows a previously unknown type of metal deformation – sinuous flow -in which metal is deformed into folds while it is being cut. New research findings, in graph at right, reveal the cutting force can be reduced 50 percent simply by painting metal with a standard marking ink, suggesting that not only can energy consumption be reduced by 50 percent but also that machining metals can be achieved faster and more efficiently and with improved surface quality. (Purdue University image/ Ho Yeung and Koushik Viswanathan)

The research team included Srinivasan Chandrasekar, a professor of industrial engineering, who is collaborating with W. Dale Compton, the Lillian M. Gilbreth Distinguished Professor Emeritus of Industrial Engineering; Ho Yeung, postdoctoral research associate, and Koushik Viswanathan,, a graduate student.

The team observed what takes place when ductile metals were cut. They used high-speed microphotography and analysis, and observed that when the metal was cut it deformed into folds. It has been believed that metals are sheared uniformly when cut. Furthermore, they observed that suppressing the folding behavior could help control the sinuous flow.

When the metal is sheared during a cutting process it forms these finely spaced folds, which we were able to see for the first time only because of direct observation in real time.

Yeung

Furthermore, they observed that painting the metal with a standard marking ink could reduce the cutting force by 50%. This was because the painted layer suppressed the sinuous flow. Chandrasekar stated that this painted layer reduced energy consumption by 50%, and also enabled faster, more efficient machining that delivered better surface quality.

"The fact that the metal can be cut easily with less pressure on the tool has significant implications," Compton said. "Machining efficiency is typically limited by force, so it is possible to machine at a much faster rate with the same power."

As the process requires less force, comparatively less vibration and heat are generated. This reduces the damage to the machined part as well as tool wear. Additionally, the cost of the process is reduced, while its accuracy increases.

The mystery of the process is that the ink was applied on the metal’s free surface, and at his place the tool was not in contact with the metal. No ink was applied between the metal and the cutting tool.

"This may sound eerie, even ridiculous, to people in the field because the cutting is not happening on the painted surface, it is occurring at some depth below," Viswanathan said.

Sinuous flow in metals

Experiments were conducted wherein only half of a sample was inked. When the tool used for cutting the metal reached the part that was inked, the force that was required got reduced by 50 % immediately. Yeung tried out with different coatings including commercial lubricants, resins, marking ink, and nail polish. A lubricant was first coated on the metal and the ink was added after that. The ink did not stick effectively to the metal surface due to the presence of the lubricant, and hence the sinuous flow suppression was less effective.

"It seems that the ink used commercially to mark metal is very good at suppressing the sinuous flow, probably because it is designed to stick well to metals," Chandrasekar said.

This finding puts forth the idea that coatings having better adhesion could help reduce the cutting force required and also produce greater sinuous flow suppression.

Chandrasekar states that though this discovery was made in metal-cutting experiments, a better knowledge about sinuous flow, its control and suppression could enable applications in other metal deformation processes including, forging, stamping, sheet-metal and machining processes.

Furthermore, intentionally increasing the sinuous flow could be used for designing new materials for energy absorption, which could find applications in structures, vehicles and armor.

Honey, liquid polymers and other such highly viscous fluids flow in a specific pattern. Natural rock formations also have fold patterns. The folds in metal observed in this experiment resemble these patterns. The fold properties in metals were analyzed using methods used in geophysics.

In continuance of this study, a model for sinuous flow is to be developed; the properties of coatings are to be studied; and the physical mechanisms involved in sinuous flow are to be analyzed.

The findings of this study have been published as a research paper in Proceedings of the National Academy of Sciences.

The National Science Foundation has provided funding for this study, which has been done through the Center for Materials Processing and Tribology at Purdue University.

References