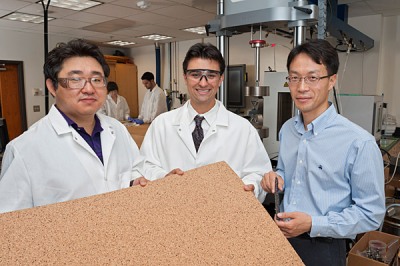

Researchers at the University of Delaware are studying the potential applications of cork as a core material in composite sandwich structures employed in aircraft, energy and automotive industries.

Researchers at University of Delaware studying applications of cork as sandwich composite material

Researchers at University of Delaware studying applications of cork as sandwich composite material

Cork is commonly associated with low-tech applications such as bulletin boards and wine bottle stoppers. The study carried out in Delaware assesses the interesting properties of cork in an attempt to identify a natural material for use in sandwich composites that would also mitigate noise. Current composite sandwich structures are made of honeycomb materials or synthetic foam cores with face sheets made of carbon-epoxy as these materials weigh less and exhibit high bending stiffness, making them suitable for aerospace applications. However, they have an undesirable feature of generating noise. The 4 to 6 inch glass lining meant to mitigate the noise only adds on to the weight and reduces cabin space. Cork has a range of desirable properties such as toughness, impact resistance, energy absorption ability, lightness of weight and most important of all, vibration and accosting damping capabilities. Moisture impermeability and good thermal properties are the result of its distinctive cellular structure.

The research team carried out a comparative study by employing two sandwich structures comprising natural cork agglomerate core and synthetic foam core of high-quality known as Rohacell, respectively. Both the cores were bonded to carbon-epoxy face sheets. The team found a 250%improvement in noise damping in the cork-based structure without compromising any of the mechanical properties. Apart from being inexpensive, cork is also environment friendly as its production is free from carbon emissions. The team has commenced work on the project’s next phase which involves the study of cork’s low-velocity impact.