Juki Automation Systems (JAS), a company specializing in high-speed SMT assembly equipment, recently received an order for six modular assembly systems, two KE-2080 Mounters and four KE-2070 High-Speed Flexible Mounters from PRIDE Industries, a nonprofit organization and recognized service supplier.

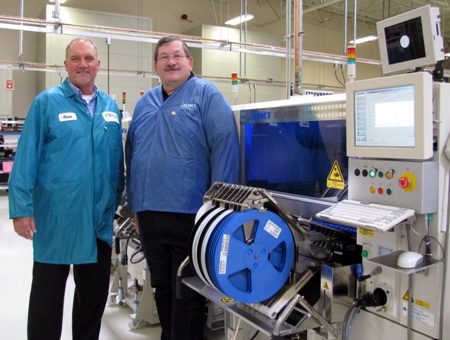

Steve Twitchell, PRIDE’s VP of Operations, and Bob Black, JAS, Inc.’s CEO

Steve Twitchell, PRIDE’s VP of Operations, and Bob Black, JAS, Inc.’s CEO

JAS’ modular assembly systems include the innovative LNC60 high resolution optical centering laser, which promotes high-speed, high accurate placement. They feature a six nozzle head, and have a placement range of 01005-33.5 mm2. The KE-2080 Mounter has a speed of 15,400 CPH and the KE-2070 of 16,000 CPH.

All JAS’ machines use the LNC60 laser to achieve the best reliability, accuracy and repeatability. The laser is equipped into the head to measure components easily during movement from the pick to the placement location. Thus, the requirement to move to an immobile or line scan camera is eliminated.

Additionally, the optical centering laser does not get affected by the color of a component, can transfer a part profile back to the database easily, and ensures that a part is available before placement. A tombstone pick check, bent nozzle detection, and the ability to identify the accurate height of the nozzle tip are additional features of the laser.

The KE-2080 and KE-2070 machines are compatible with Juki’s existing feeders and trolleys. They also include powerful line optimization software, auto-pick correction feature and rugged trolley carts. The auto-pick correction feature reduces setup time and assures precise picking of even the tiniest components.