Joining Technologies, a company specializing in industrial laser applications, has reported the offering of Application Laboratory Days (AppLab Day) by Joining Technologies Research Center for engineers showing interest in exploring projects that might gain from laser additive production.

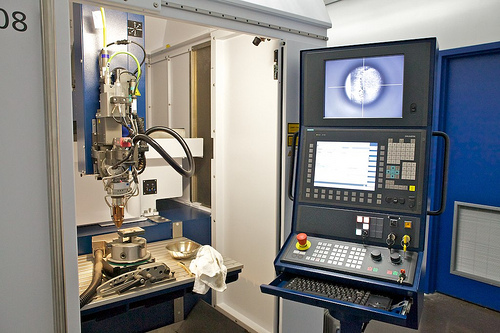

AppLab Day sessions will be conducted at Joining Technologies Research Center’s high-tech laser additive manufacturing research and development facility situated in East Granby, Connecticut. Under the guidance of the center’s laser additive specialists, design engineers can conduct their research work to create and explore samples utilizing the center’s equipment.

Working with Joining Technologies’ skilled scientists, engineers attending the AppLab Day sessions will directly learn the working principle of the laser additive process and the role of laser cladding of metal powder alloys in the improvement, repair or freeform material in valve, power generation, aerospace and OEM-supplied components.

After performing research works in the applications laboratory, Joining Technologies will provide continual support to customers through detailed research process, to the process assessment and certification phase, and eventually into full scale production.

Joining Technologies Research Center’s Director of Research and Development, Tim Biermann stated that the center’s new AppLab Day provides the bridge between shop floor production laser cladding and university-level research. Hand in hand with the center’s research specialists, design engineers will be able to learn the role of laser cladding in the improvement of current processes, or in the development of new processes and products.