Panasonic has devised an artificial photosynthesis system that enables carbon dioxide conversion into organic materials through illumination with sunlight at an unprecedented efficiency of 0.2%, which is equal to that of real plants utilized for biomass energy.

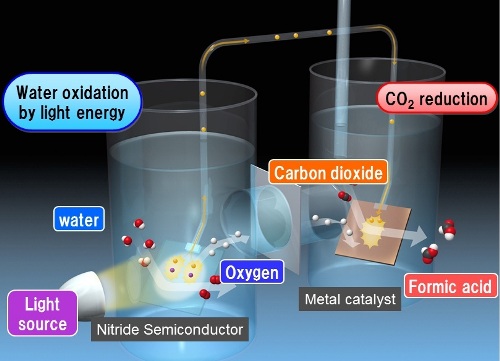

Schematic view of artificial photosynthesis system

Schematic view of artificial photosynthesis system

A nitride semiconductor plays a key role in making the system simple and effective. This advancement paves the way to realize a system to capture and convert carbon dioxide wasted from industrial activities, power plants, and incinerators.

Carbon dioxide causes greenhouse effect and is directly linked to the fossil fuel exhaustion problem. Artificial photosynthesis is the answer for these issues. Panasonic's artificial photosysnthesis system features a combination of simple structure and high-efficiency carbon dioxide conversion, which is capable of using focused light or direct sunlight.

Panasonic discovered initially that a nitride semiconductor is capable of exciting electrons with adequate high energy for the reduction reaction of carbon dioxide. Nitride semiconductors can be utilized as a photo-electrode for carbon dioxide reduction. A photo-electrode’s performance can be enhanced by fabricating a device structure using the thin film technique for semiconductors.

The carbon dioxide reduction occurs on a metal catalyst at the nitride semiconductor photo-electrode’s opposite side. The metal catalyst is crucial in the selection and acceleration of the reaction. Since the system consists of only inorganic materials, which can perform carbon dioxide reduction with minimum energy loss, the quantity of reaction products is accurately proportional to the power of light.

The system comprising the metal catalyst and nitride semiconductor produces formic acid as main product from carbon dioxide and water in the presence of light at 0.2% efficiency. The formic acid is a key chemical for fragrances and dyes. On this advancement, Panasonic owns 18 domestic and 11 overseas patents, which include pending applications.