At FachPack trade fair to be conducted in Nuremberg, BASF will exhibit its full range of particle foams for packaging applications and to protect high-value products. BASF specialty foams are ideal for a myriad of packaging applications, allowing customers to safeguard their highly sensitive items. Neopolen, a closed-cell particle foam, is a fitting material for reusable transport containers and recyclable packaging. It is offered as Neopolen E (expanded polyethylene) and Neopolen P (expanded polypropylene) in the market.

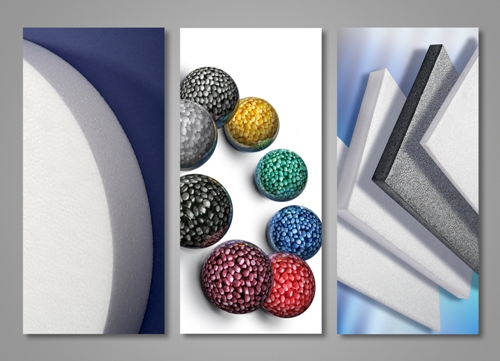

From left to right: E-por, Neopolen P and Neopolen E (photo: BASF 2012)

From left to right: E-por, Neopolen P and Neopolen E (photo: BASF 2012)

Neopolen E is capable of protecting sensitive surfaces as it demonstrates a unique level of softness. This foam is offered in panel form in black and white colors with densities of 22, 32 and now 52 kg/m3. It features better processing qualities such as cutting, hole-punching and milling, thus paving the way to a variety of possible applications.

Neopolen P is offered in particle form and can be foamed into a broad range of components with the help of automated molding systems. It is possible to adjust the density of these molded parts, offering higher degree of freedom and flexibility in their design. Both foams have low weights, high energy absorption levels and better resilience, which delivers a great degree of protection to products from repeated impact load. Moreover, Neopolen is devoid of chemical blowing agents, 100% recyclable and absorbs small amount of water.

E-por, a tough-elastic foam and an advancement of expandable polystyrene, is ideal for impact-resistant disposable packaging to provide protection to expensive electronic devices. The devices’ weight and sensitivity decide the level of packaging. E-por delivers a cost-effective solution in these cases. E-por is a complicated formulation of various polymers that interplay with themselves as well as with the blowing agent, making it the first tough-elastic foam that is storable, producible and recyclable like classical Styropor. Moreover, the specialty foam has an aesthetic texture and look, and improved resistance to solvents.