Researchers at Purdue University have developed a method for mass production of nanoresonators that can be used for decreasing the congestion in airwaves. These nanoresonators may aid in improving the quality and continuity of cell phone calls and information downloads.

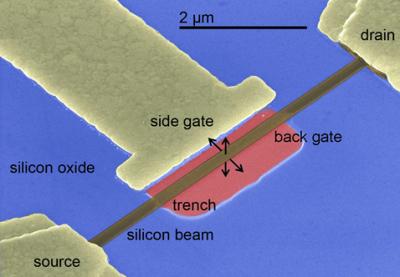

This image from a scanning electron microscope shows a tiny mechanical device, an electrostatically-actuated nanoresonator, that might ease congestion over the airwaves to improve the performance of cell phones and other portable devices. (Purdue University image)

This image from a scanning electron microscope shows a tiny mechanical device, an electrostatically-actuated nanoresonator, that might ease congestion over the airwaves to improve the performance of cell phones and other portable devices. (Purdue University image)

When voltage is applied to nanoelectromechanical resonators, which are nanoelectromechanical systems (NEMS), a tiny beam of silicon in the resonator vibrates based on the amount of voltage applied. This beam is attached at two ends of the device. It has a length of about 2 µ and width of 130 nm. The beam can be tuned and can be made to vibrate vertically and horizontally. When compared to other resonators, these nanoresonators control their vibration frequencies in a better manner. Tunable filters are difficult to produce using electronic components such as inductors and transistors. Nanoresonators consume significantly less power and also perform better.

The frequency of the vibrating beam can be measured precisely. This frequency varies when particles land on the beam. Analysis of the change in frequency will enable measurement of minute masses. These sensors demonstrate potential for being used to detect DNA or proteins in devices such as breath analyzers, food and water quality monitoring devices and for defense and security applications, apart from being used as future cell phone filters.

The nanoelectromechanical resonators can be fabricated with a nearly 100% yield, and the method developed enables fabrication on a large-scale. The conventional silicon-on-insulator (SOI) fabrication method used for standard manufacture of electronic devices has been used for producing these nanoelectromechanical resonators. These resonators can be used along with other standard electronic systems due to the compatibility of SOI with CMOS.