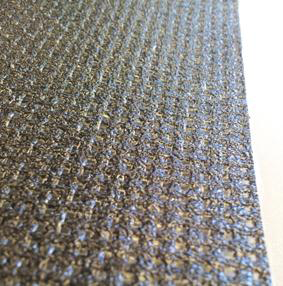

CHOMARAT is launching TPreg, its new range of continuous reinforcements for the production of thermoplastic composites.

Chomarat offers innovative solutions in response to the problems of weight reduction and mass production in the automobile industry. Thermoplastic composites have many advantages: speed of conversion processes, little emission of volatile matter, thermoformability and recyclability. Their development has however until now been held up by expensive conversion processes. Chomarat is launching its range of innovative TPreg continuous reinforcements opening up new prospects for manufacturers while offering them the possibility of using equipment and processes already in place. “CHOMARAT has developed a thermoplastic reinforcement suited to problems in the automobile market: mechanical performance and flexibility in use. TPreg is a conformable reinforcement that preserves perfect orientation of the fibres. It can be designed with a diversity of materials (carbon fibre, glass fibre, etc.) and in different widths. With various impregnation levels in development, the range is suited to various production processes and opens up new technicoeconomic prospects for the market” indicates P. SANIAL, R&D Manager at CHOMARAT.

This new range finds applications in numerous sectors such as automobile or sports and leisure.

Chomarat innovates, Chomarat forms part of the chain of partners awarded a prize at the JEC Paris exhibition in the thermoplastic category.

CHOMARAT is participating in the automobile forum to present its innovating solutions for thermosetting and thermoplastic composites on Wednesday 13 March from 10.30 am to 1.30 pm

Second-generation composites advance with C-PLY ™: discover them at stand Q25

Launched in 2011, the C-PLY™ project, under the leadership of Professor Tsai, has demonstrated that an optimised design of the composites makes it possible to obtain significant savings in weight (up to 30%). Currently the working group is entering a new phase and is demonstrating that the use of C-PLY™ in a manufacturing phase with automated laying processes makes it possible to obtain productivity gains never before obtained. Downtime for ATL (Automated Tape Laying) robots is reduced by a factor of 3 to 7 depending on the geometry of the part. The latest results of the working group, composed of researchers and manufacturers, will be exhibited at the show: stand Q25.

Chomarat innovates, Chomarat won an award at the first Boston JEC show for its C-PLY carbon reinforcements.

CHOMARAT is participating in the aeronautical forum in order to present the possible innovations in terms of design and production with C-PLY™ on Wednesday 13 March from 2.30 pm to 5.30 pm.