The demand for high quality solar cells is increasing worldwide. This imposes pressure upon cell producers to sort cells reliably and fully automatically. Camera-based quality inspection and cell clas-sification can be integrated into existing cell testers/sorters. At SNEC 2013 VITRONIC presents to the Chinese PV industry its VINSPECsolar VCOFLC1 camera system that enables exact and reliable front print and color inspection, better than human eyes can do.

Camera-based quality inspection system

Camera-based quality inspection system

Tier One customers require high quality solar cells. Especially sorting into different color classes is a main scope at Asian factories. Therefore many Asian solar cell producers consider how to retrofitting their existing production plants. The new VINSPECsolar VCOFLC1 camera system combines front print and color inspection, and performs exact and reliable quality inspection and cell classification. VINSPECsolar VCOFLC1 enables easy operation, calibration and reliable and robust performance at competitive pricing. VITRONIC provides a standard calibration tool to define the color classes and borderlines. Even if several cell testers have to be operated and tool matching is required: the set up process needs to be done only once and the classification rules can be copied to all other testers.

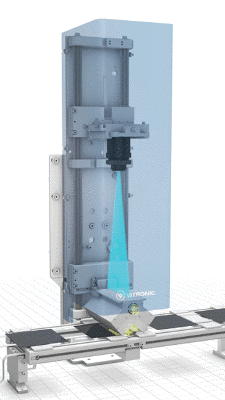

Technical description

The inspection system can be used for both mono and multicrystalline silicon cells. Its throughput achieves more than 2,400/h, and the sorting pureness is higher than 99.8 percent. The sensor box consists of a color line scan camera with four 4,096 (4k) pixels lines, a white LED illumination module, a backlight and a computing subsystem. The software – developed by VITRONIC - provides automated, fast tool calibration and tool matching, a graphical user interface comprising yield control tools for rapid intervention and process adjustments, statistics and visualization of all quality relevant features of current and recently tested cells.