ADERIS® is launching the first line of hybrid structural adhesives, called INES™ for INterlaced Elastomer NetworkS. The new adhesives offer high structural and damping performance.

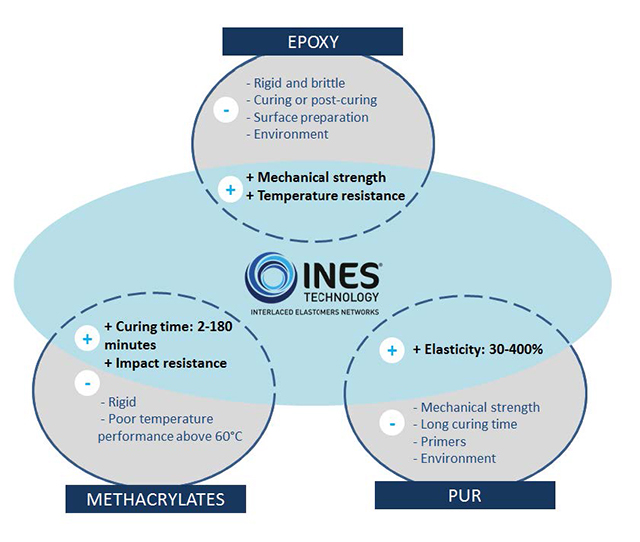

The INES line combines the performance of three different adhesive bonding technologies: the resistance and mechanical strength that only epoxies can usually offer; the elasticity provided by polyurethanes (PUR); and the fast assembly rate enabled by methacrylates (MMA).

This is the first time that a structural adhesive combines elongation, low modulus and high mechanical performance with high impact, peel and shear strength, for a range of temperatures from -80° to +140°C.

- Peerless compatibility between heterogeneous materials

There is no need for a primer with INES™ to obtain high performance: the bond remains flexible, yet allows rapid handling of the bonded parts. Furthermore, INES™ can be used to join the broadest range of heterogeneous materials found in the market: treated metals, engineering composites*, thermoplastics (ABS and PC), glass, zinc, etc.

“Our durable high-performance multi-material adhesives target many different applications, and can create reliable adhesive bonds where welding and riveting are now used, in particular to assemble composite materials and metals. Our adhesives are already used by world-renowned companies for large parts in sectors as demanding as automotive (chassis, bodywork), boating, railway, and even aerospace!”, said ADERIS® Innovation Director Arnaud Curet.

*Engineering composites include carbon fibre, CFRP, SMC, BMC and RTM

- INES™: a combination of exceptional properties

INES™ has excellent elasticity (70% pure elasticity over an elongation range) in combination with high strength (250 kg/cm² for shear on steel and up to 100 kg/3.5 cm for peel). These properties offer exceptional technical performance for high-stress bonding applications: thanks to its high structural performance, the INES™ line acts like a damper jack when the assembly is subjected to vibrations, over a range of temperatures from -80° to +140°C (the product’s two glass transition temperatures). The damping feature is also acoustic: INES™ mitigates noise, especially when it is used on automotive parts. “INES™ is a truly ground-breaking technology that enables manufacturers to make assemblies safer over the long term and for which the extremely high level of performance and reliability inspires greater confidence in the bonding process”, pointed out Mr Curet.

In addition, unlike the adhesives on the market today, the INES™ range performs at ambient temperature, which means considerable time and energy savings for users.

- By 2018, 50% of the materials ADERIS® uses will be bio-sourced

According to Mr Curet, the company will be using bio-sourced, recyclable materials to the extent of 50% within five years. “ADERIS® is at a turning point of its development, and we hope to position ourselves in sustainable mobility markets, thanks not only to the innovative performance offered by our products, but also to the minimized carbon footprint they can provide to our customers”, he said.

With more than 30 years of experience in adhesives and sealing technology, and facilities located near Paris (France), ADERIS®develops and produces innovative structural adhesives for the aerospace, electronics, automotive, railway & transportation, building & construction, and sports & leisure sectors. The company has already filed five international patents and expects that exports will account for nearly half of its sales by 2014.

ADERIS® is launching the first line of hybrid structural adhesives, called INES™ for INterlaced Elastomer NetworkS. The new adhesives offer high structural and damping performance.

A GROUND-BREAKING TECHNOLOGY OFFERING UNIQUE PERFORMANCE

ADERIS® is launching the first line of hybrid structural adhesives, called INES™ for INterlaced Elastomer NetworkS. The new adhesives offer high structural and damping performance.

A GROUND-BREAKING TECHNOLOGY OFFERING UNIQUE PERFORMANCE

INES™ combines the performance of epoxy, methacrylate and polyurethane resins

Press Contacts: AGENCE APOCOPE - Dorothee Davide - Justine Rohee

Tel. 01 45 78 87 37 - [email protected]