By maintaining a low noise floor during part measurement you can be assured of measurement integrity. All axes of the Taylor Hobson 500 series are controlled for waviness, straightness and noise, whether using the spindle, column or arm.

Measurement of surface finish and form can only be achieved through a combination of:

– Low noise movement/measurement axes

– High resolution gauging technology

– High accuracy linear and rotary scales

– Arcuate correction

For any mechanical structure whether it is a machine tool or a measuring instrument the noise floor is paramount. Any noise in the system such as tool chatter or stylus vibration will affect the integrity of the machined part and subsequent measurement.

The Talyronds greatest asset is its world leading noise floor measuring less than 30nm Rq...

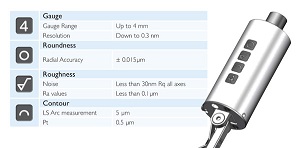

…. And now with the new Talymin 6 multi-functional gauge

– World leading 4 mm range with 0.3 nm resolution

– Maintains constant force regardless of attitude or orientation

– Enables measurement of angle, radius and form with respect to the part axis

Contour, surface finish and roundness

- LS Arc Form Error less than 0.5 µm

- LS Arc Radius accuracy less than 5 µm

- System noise less than 30 nm

- Resolution down to 0.3 nm

- Roundness deviation 0.015 µm