Oct 15 2013

MedPlast Inc., a technology and innovative process leader in manufacturing support for Healthcare markets, announces the acquisition of U.K.-based Orthoplastics, Ltd. Orthoplastics is a leading custom manufacturer of ultra-high molecular weight polyethylene (UHMWPE) products and components for the global OEMs serving the orthopedic device implant market.

With a rigorous quality compliance system and a strong customer service focus, Orthoplastics is one of the major UHMWPE suppliers to the strictly regulated orthopedic implant market. Orthoplastics not only supplies UHMWPE material, but also produces implantable orthopedic components to customer specifications.

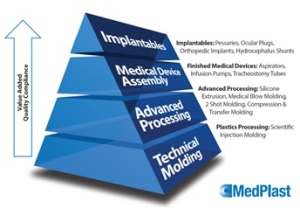

“Through this acquisition, MedPlast can accelerate its growth into the medical device assembly and implantables markets,” Harold Faig, CEO of MedPlast, said. “The combination of MedPlast and Orthoplastics represents tremendous opportunities for both firms and for our customers,” added Faig. Orthoplastics gains production capacity for components, while MedPlast is able to expand its footprint in Europe for medical applications. “Orthoplastics becomes a key part of our strategy to deliver comprehensive processing technologies to the global medical device market,” said Matt Langton, Executive Vice President of Sales and Marketing for MedPlast. This will provide our current and future customers with a wider range of capabilities that become even more valuable as the design of medical products grows increasingly sophisticated and regulated.

“This acquisition allows MedPlast to combine its technical capabilities with Orthoplastics’ implantable technologies to become a significant player in the implantable market,” added David Brooks, Managing Director of Orthoplastics. MedPlast brings expertise in injection molding, medical blow molding, silicone extrusion, compression and transfer molding, liquid injection molding (LIM), two-shot molding, over molding, insert molding, multi-component molding, and precision mold making. Orthoplastics has developed technology to produce premium grade UHMWPE material to the highest quality standards, as well as patenting a method of gamma cross linking in bulk with close dosage control – important to orthopedic device customers. Orthoplastics capabilities include direct compression molding (DCM), ram extrusion, annealing, machining and finishing, inspection and laboratory testing.

“Driven by an increasingly aging population and healthcare legislation, MedPlast’s robust product line addresses the need for effective orthopedic solutions in both developed and developing countries,” said Faig.