A new production approach first presented by ELMET at K 2013 is directed at the processing of liquid silicone rubber (LSR) which cures under UV-light from a LED source.

This method eliminates the high curing temperatures required for conventional heat-curing LSR grades. Hence, also thermoplastics with a low melting point, including polypropylene (PP), polyethylene (PE) or polymethyl methacrylate (PMMA), are suitable for two-component injection molding with LSR as the soft component, whereas otherwise materials providing higher temperature resistance at higher prices are required, such as polyamide (PA) or polybutylene terephthalate (PBT). Thus a broad diversity of new applications is opened up in the production of hard/soft composites using LSR as the soft component.

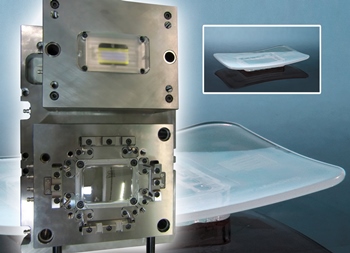

An application example is a soap dish made of translucent polypropylene (PP) which has a directly molded-on silicone support base. For making this item, ELMET had developed a complete production system in cooperation with the machine manufacturer Engel and the raw materials supplier Momentive. This solution was then built on a turnkey basis.

Credits: Elmet.

Credits: Elmet.

One key element of the system is an innovative injection mold operating in a standard injection molding machine (type: e-mac170/50, manufacturer: Engel). In this mould, which has steel sealing surfaces (eliminating wear and hence, the need for replacement) on both mould halves, the molding is initially produced from UV-transparent PP. After demolding and relocating this PP part to a higher mold region, the LSR base is then injection-molded onto it. Finally, the silicone component is exposed to UV light through the PP article for curing.

The light sources used in this application are rugged LED lamps which are noted for their long service life. Moreover, the activation point and ON time duration of these LEDs can be accurately matched to the curing reaction so as to minimize energy input and cycle time.

A further innovative component of this system is the new air-powered injection unit for the LSR component. Integrated into the machine control system, it provides a very precise, repeatable injection pressure and velocity for exceptional process stability. The space-saving TOP 1000 Mini metering system is another novelty; it delivers an accurately metered amount of LSR into the injection unit. The cross-linking agent and dye are introduced using a standard additives line.

At K 2013, this full-fledged production system designed specifically for processing UV-light curing LSR will be shown in operation at Momentive Performance Materials, Stand G45 in Hall 08a.

ELMET Elastomere Produktions - und Dienstleistungs GmbH of Oftering/Austria, established in 1996, is an internationally successful developer and manufacturer of LSR metering systems, fully automatic injection molds, valve gate cold decks, and turnkey equipment for processing silicones and rubbers. Including the staff of its ELMET North America sales and service organization, the company employs around 150 people.