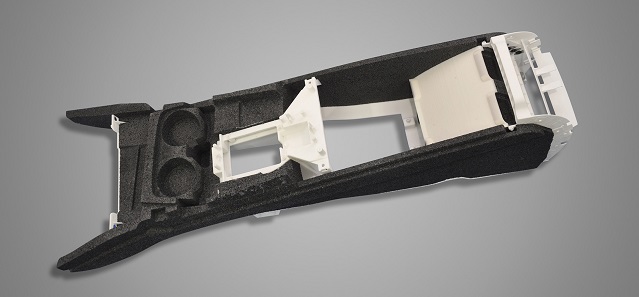

Plastic automotive components that received prizes at the 2013 SPE European Automotive Division Award ceremony for the Body Interior category included an innovative center console to which BASF had made a key contribution with its materials expertise on Neopolen® particle foam.

This joint project by BMW Group, BASF, and other partners was a recipient of the “ 15th SPE Automotive Division Award 2013. ” Considered the most prominent award for plastics in the automotive industry, the prize recognizes the most innovative and creative solutions in the field.

BMW Group is the world’s first car maker to use polypropylene foam as a visible contour material on an innovative center console. Neopolen P foam from BASF helps reduce weight by around 30 percent compared to the previous solution. Molding technology specially developed for this purpose eliminates steps otherwise necessary for the conventional process – production now consists of only a single step. Use of Neopolen also allows additional functions to be integrated into the center console. For example, the foam molding process can already provide for ventilation channels for the air-conditioning system serving the rear of the car’s interior.

One process step for a new lightweight structural element

The process starts by laying a thermoplastic substrate into the mold, filling its cavity with foam beads, and using steam pressure to weld these two elements into a molded part. During the same step, movable bars place smooth sheeting on the molded part and firmly bond it with the material. At the same time, the bars’ grain structure and the heat from the steam lend the sheeting its typical texture. This gives the component an appealing surface with a softer feel. BMW Group will be using this lightweight structural element in its cars in the future. As the next step, the company will be selecting the models for which the component will be part of series production.

Neopolen P – wide range of applications

Neopolen P has very good noise insulation properties, low weight, and high thermal resistance. This particle foam combines high energy absorption – even after multiple impact loads – with good resilience and isotropic deformation performance. Its property profile, which also includes low moisture absorption and good resistance to chemicals, opens up a wide range of applications in sectors from packaging and transportation to sport and leisure.