Princeton researchers have discovered that bursting bubbles can push droplets of a material down into a liquid as well as into the air above.

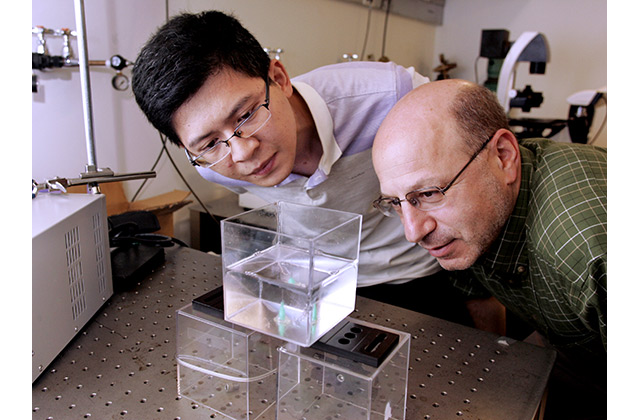

Image Sourced by Frank Wojciechowski for the Office of Engineering Communications

It is a well-known fact that bursting bubbles release aerosol droplets, but a new study performed by Princeton researchers has revealed that the same process can also disperse small droplets of a surface material into a liquid. This finding has huge potential in science and industrial sectors, where mixing of liquid solutions is a major concern.

Howard Stone, lead researcher, informed that this significant breakthrough was made when the researchers covered the water with oil and found that the bursting bubble process appeared to push small droplets of oil into the water.

Then, using a number of experimental methods, they revealed the factors that cause the bubbles to burst and how the water and oil mixture is affected by this phenomenon. This finding provides a better understanding about the mixture of non-soluble liquids, which is an important process in many fields, ranging from oil spill cleanups to drug manufacturing.

Jie Feng, a student in Stone's lab, further explained that the bursting bubbles caused the layer of oil to scatter as nano-droplets into the water. This is a novel form of mass transport associated with bubble bursting, he added.

In one experimental approach, the researchers observed that after the bubbles passed through the mixture, the water in the container transformed from clear to transparent.

This change indicated that tiny objects had scattered in the lower phase of water.

To gain a better insight into this phenomenon, a high-speed camera was used to capture the steps involved in the final pop of a bubble.

It was found that the breakdown of the bubble produced a pressure wave under the bubble and a certain amount of liquid was pushed away from the collapsing void due to this wave.

Since the nano-droplets are very small, the researchers covered the water with a thin layer of latex particles and observed the movement of the particles in the water.

A layer of UV-sensitive material was also added to the water and then light was used to harden the droplets. However, in order to form nano-droplets, adequate amount of surfactant is required.

The researchers concluded that bubbles can have a major impact on many industrial systems. For instance, this approach is used to produce nanoemulsions and consumes significantly less amount of energy when compared to standard mixers, thus making it more efficient and cost-effective. This type of bubbling is also suitable for mixing insoluble liquids.