Researchers from Tohoku University have developed a new method to produce defect-free graphene nanoribbons (GNRs). The technique produces GNRs with periodic zigzag-edge regions by using a bottom-up fabrication method. The length distribution and growth direction of the GNR are controlled by this method.

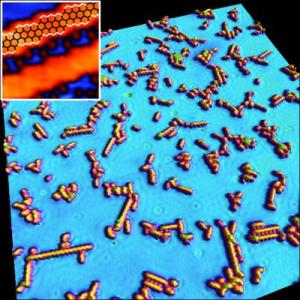

Graphene nanoribbons are fabricated by molecular assembly on a Cu(111) substrate. On this surface system, GNRs on grow in six azimuthal directions exclusively. White lines in the inset highlight the zigzag edges of a ribbon. Credit: Patrick Han

Graphene nanoribbons are fabricated by molecular assembly on a Cu(111) substrate. On this surface system, GNRs on grow in six azimuthal directions exclusively. White lines in the inset highlight the zigzag edges of a ribbon. Credit: Patrick Han

Graphene holds great promise for future high-speed transistors. Graphene’s structure controls its properties and the ribbon width controls the bandgap of GNRs. However, the abilities of other edge conformations have not been confirmed due to fabrication issues.

This research was led by Patrick Han and Taro Hitosugi, Professors at the Advanced Institute of Materials Research (AIMR) in Tohoku University. Han stated that inert substrates were used for bottom-up molecular assemblies and the molecular chemistry and the intermolecular forces decide the manner in which the molecules assemble. Presently, no molecule can be assembled to create zigzag-edge GNRs.

The AIMR researchers utilized a copper surface for targeting the zigzag edge, by adding new intermolecular interactions and substrate-to-molecule interactions. They used a precursor molecule that had the capability to form armchair-edge GNRs. STM images revealed that copper had a different molecular assembly and provided zigzag-edge GNRs.

The copper substrate’s surface reactivity has a significant effect on surface growth direction and GNR length distribution. Using this method, shorter ribbons were produced in six surface azimuthal directions, which could be utilized for producing graphene interconnections by self-assembly between prefabricated structures.

According to Han, this method may lead to new possibilities in the development of self-assembling, single graphene systems.