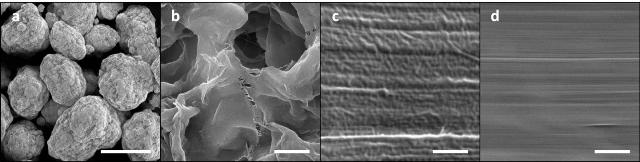

This sequence of scanning electron microscopy (SEM) images demonstrates drastic changes in polyethylene surface morphology resulting from the fabrication process. The initial polymer particulate material resembled tightly wound balls of string (a). Comparing this to the extruded sample (b), however, polymer disentanglement as a result of the high shear rate Couette-based extrusion process is evident. SEM images of 50× (c) and 100× (d) drawn films. As shown, film structure is uniform fibrous with minimal defects. Scale bar represents 100 microns (a), and 2 microns (b-d). Image credit: Technology

This sequence of scanning electron microscopy (SEM) images demonstrates drastic changes in polyethylene surface morphology resulting from the fabrication process. The initial polymer particulate material resembled tightly wound balls of string (a). Comparing this to the extruded sample (b), however, polymer disentanglement as a result of the high shear rate Couette-based extrusion process is evident. SEM images of 50× (c) and 100× (d) drawn films. As shown, film structure is uniform fibrous with minimal defects. Scale bar represents 100 microns (a), and 2 microns (b-d). Image credit: Technology

The molecular alignment of polymer fibres plays a key role in enhancing the thermal and mechanical properties of polymeric materials. However, current fabrication techniques for highly aligned polymer films (HAPFs) are restricted to lab-scale production.

The new scalable fabrication process allows energy-efficient polymer fibres to be produced at low cost to suit various applications such as heat exchangers, electronic packaging and heat transfer. The researchers have successfully resolved the challenges involved in scaling and regulation of process variables.

By taking advantage of the inherent high thermal conductivity of polymers' C-C bond, and a corresponding reduction in chain entanglements and defects, this process opens the door for transforming materials which are traditionally considered thermal insulators into something that is ideal for use in heat transfer applications.

Professor Gang Chen, Ph.D, of the Massachusetts Institute of Technology and Principal Investigator on the paper.

In this experiment, researchers controlled the molecular chains of the polymers through disentanglement and macroscopic plastic deformation-induced alignment in order to tweak their material properties.

When compared to traditional fabrication methods, this new technique has numerous benefits such as uniform and crystalline film production by constant-force adaptive-thickness mechanical drawing system, automated scalable platform and enhanced chain disentanglement by using Couette flow. The disentangled structure in the extruded polymer gel was made to freeze through liquid N2 cooling.

Ultra-high molecular weight polyethylene was used in the experiment, resulting in over 15m long HAPFs with crystallinity more than 99%. This technology can be combined with the existing methods of fabricating aligned polymer fibres. Film forms of polymeric fibres find applications in biomedical treatments, electronic systems and heat exchangers.

The team at MIT are now hoping to characterise the changes in polymeric structures with respect to the draw ratio, correlate the properties of the material by changing molecular weights and analyse the orientation of highly aligned polymers. The integration of this technology with electrically conductive nanofiller composites improves the electrical conductivity, thermal conductivity and tunable strength of composites for commercial applications.