Researchers at the Oak Ridge National Laboratory have unravelled the mystery of the deformation mechanism found in metallic glasses.

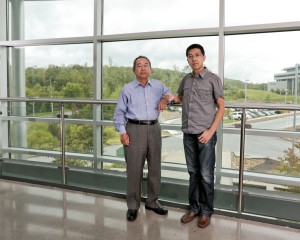

Joint Institute for Neutron Sciences Director Takeshi Egami, left, and Wigner Fellow Yue Fan, holding a metallic glass thumb drive, discovered the mechanism by which metallic glass deforms. Credit: Jason Richards, ORNL

Joint Institute for Neutron Sciences Director Takeshi Egami, left, and Wigner Fellow Yue Fan, holding a metallic glass thumb drive, discovered the mechanism by which metallic glass deforms. Credit: Jason Richards, ORNL

Metallic glass is a wear-resistant, magnetically exploitable and moldable material, which is also able to demonstrate three times the strength of steel.

Whilst most metals are crystalline in nature, metallic glasses have an amorphous atomic structure. As metallic glass is relatively stable, it can be precisely cast into molds and does not become crystalline again.

This material is currently used to produce resilient coatings, energy efficient transformers, scalpel blades and biocompatible bone implants but its application is still very expensive. If the brittle nature of metallic glasses could be addressed, it could be used in the manufacture of watches, skis, automobile bodies, smartphones casings and computer chip coatings.

When analysing the deformation of metallic glasses using a computer simulation, the researchers discovered that before the material shattered, patches of around five atoms exchanged atomic bonds with one another. Previously it has been thought that between 20 and 600 atoms were involved in this process.

In this study, metallic glasses were heated to a temperature of 2,000K before being cooled to nearly absolute zero. At this temperature atoms cannot move much and, when compared to slowly cooled glass, more five-atom deformation triggers occurred in the rapidly cooled glass thus creating glass with greater ductility.

Due to disordered atomic packing, the behaviour of glass is not fully understood in the field of solid-state physics as liquids and glasses do not possess periodicity which can helpful when analysing solids.

Mechanism of glass deformation

The evolution of metallic glass is governed by its potential energy landscape. The researchers analysed ‘saddle points’ between neighbouring minima during the deformation process. Saddle points are the highest energy points during atomic interactions - only when five atoms have sufficient energy to climb and cross the saddle points does the deformation process occur.

The findings of the study may help to control ductility in metallic glasses. The paper on this study, ‘How Thermally Activated Deformation Starts in Metallic Glass’, has been published in the journal Nature Communications.