Researchers have developed an advanced polymer nanomaterial that is electrically conductive, strong, and yet flexible enough to be folded easily. The material offers a new approach to improve aerospace components, flexible armor, water filtration, and electrical energy storage. The research was a joint effort of the Dalian University of Technology in China and the Drexel University.

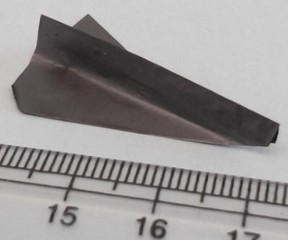

MXene-polymer nanocomposite material, created by researchers at Drexel University, is both strong and conductive and flexible enough to fold. Credit: Drexel University

MXene-polymer nanocomposite material, created by researchers at Drexel University, is both strong and conductive and flexible enough to fold. Credit: Drexel University

This flexible material is the latest focus of research which is being conducted on a series of composite 2D materials called MXenes. Since the development of the carbide material in 2011, the researchers have been exploring ways to leverage the physical and chemical properties of it to develop conductive materials that would have many useful properties.

They consequently developed a process called intercalation which helped in tapping the various abilities of MXenes. In this process, different chemical compounds are added in a liquid form so that the molecules are able to settle between the layers of the MXene material and thus change the material’s chemical and physical properties. Some of the findings revealed that MXenes indeed are potential source for energy storage.

In order to create the conductive polymer nanocomposite, the titanium carbide MXene was intercalated with polyvinyl alcohol as well as with a polymer called polydiallyldimethylammonium chloride (PDDA).

MXenes’ surface has many functional groups, which forge a strong bond between the polymer molecules and MXene flakes and at the same time preserve the metallic conductivity of nano-sized carbide layers.

The outcome is a nanocomposite that has a combination of unique properties, shows excellent ability to store electric charge over the original MXene, and has remarkable strength. The findings of MXene testing have been published in the Proceedings of the National Academy of Sciences.

The tests also demonstrated the hydrophilic properties of the flexible nanocomposite material. This material does not dissolve in water and remains stable, thus implying potential applications in water treatment systems for desalinization or water purification. Since the material is flexible, it can be easily folded into a tube. This characteristic increases its mechanical strength and hence could be used in a range of products.

“We have shown that the volumetric capacitance of an MXene-polymer nanocomposite can be much higher compared to conventional carbon-based electrodes or even graphene," said Chang Ren, Gogotsi’s doctoral student at Drexel. "When mixing MXene with PVA containing some electrolyte salt, the polymer plays the role of electrolyte, but it also improves the capacitance because it slightly enlarges the interlayer space between MXene flakes, allowing ions to penetrate deep into the electrode; ions also stay trapped near the MXene flakes by the polymer. With these conductive electrodes and no liquid electrolyte, we can eventually eliminate metal current collectors and make lighter and thinner supercapacitors".