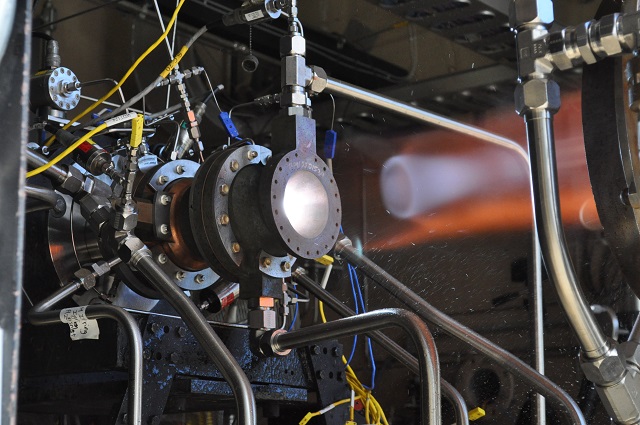

Rocket engine parts made by 3-D manufacturing in copper alloy undergo hot-fire testing at NASA Glenn with Aerojet Rocketdyne. Image Credit: NASA

Rocket engine parts made by 3-D manufacturing in copper alloy undergo hot-fire testing at NASA Glenn with Aerojet Rocketdyne. Image Credit: NASA

NASA recently partnered with AR and successfully completed the initial hot-fire tests using copper alloy materials on a thrust chamber assembly of an advanced rocket engine.

The Game Changing Development Program in the Space Technology and Mission Directorate of NASA has been investing actively in 3D printing research and has co-funded a test series with Aerojet Rocketdyne (AR) at the Glenn Research Center. Additive manufacturing or 3D printing is increasing in popularity and is transforming the cost, speed and flexibility of building and designing future machines for earth and space applications.

The rigorous test sequence confirmed for the first time that 3D manufactured copper components could withstand the pressure and heat needed by combustion engines used in space launches.

NASA and AR conducted 19 hot-fire tests on four thrust chambers and injection assembly configurations, exploring several mixture ratios and injector operability points, and concluded that it was completely successful in comparison with the planned test program.

The successful hot fire test of subscale engine components provides confidence in the additive manufacturing process and paves the way for full scale development.

Tyler Hickman, lead engineer for the test at Glenn.

The tests mark a key breakthrough in the certification and development of several materials used in manufacturing. Copper alloys offer new challenges to 3D printing. The material properties and microstructure are much below typical copper. Hence they have gone through a well-ordered process to optimize and finalize processing characteristics and have done thorough material tests to know the performance of the alloy structurally.

According to the Glenn project manager, additively manufactured metal propulsion parts are definitely a paradigm shift for the aerospace industry. NASA and its partners invest in 3D printing, which will enhance efficiency and reduce the cost of space launches as well as other earth applications.

References