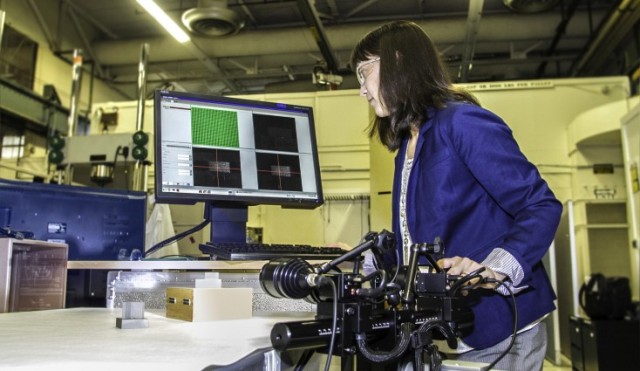

Amanda Wu images an additively manufactured part using digital image correlation. Photo by Julie Russell/LLNL

Amanda Wu images an additively manufactured part using digital image correlation. Photo by Julie Russell/LLNL

Researchers at Lawrence Livermore National Laboratory (LLNL) have developed a novel method for measuring the residual stresses in 3D printed metal parts. Powder-bed fusion additive manufacturing (AM) is a type of 3D printing process that uses a high-energy laser beam for fusing metal powder particles. In this method the metal parts are produced using a layer-by-layer method.

Components and parts of high-quality can be manufactured using this AM process; however, residual stresses are generated due to the repetitive rapid heating and cooling process that occurs at the spot where the powder is melted. Residual stresses can affect structural integrity, mechanical performance, and can cause a loss of shape leading to the failure of components and parts.

The researchers combined stress-relieving methods with digital image correlation (DIC) to accurately measure surface-level residual stresses.

A dual camera setup was used to image a part before and after it was taken away from the build plate.

If no residual stresses exist, surface distortion should not occur and the parts should fit together perfectly. However, if they do exist then distortion will occur and deformation can be measured by comparing the images before and after part removal.

Researchers at Los Alamos National Laboratory (LANL), who collaborated in this project, used neutron diffraction (ND) technique to validate the results obtained by the DIC method. The ND technique involves firing a neutron beam and detecting its diffraction to measure residual stresses. However, a high-energy neutron source is needed for this analysis which is available only in three U.S. federal research labs.

The ND experiments showed that DIC was a reliable method for measuring the residual stresses in parts and components produced by powder-bed fusion AM. Furthermore, they showed that reducing the length of the laser scan vector and rotating it helped in reducing residual stresses.

The data obtained from this study will enable optimal calibration of processing and scanning parameters for producing 3D printed metal parts with minimal residual stresses. This study has been reported in the journal Metallurgical and Materials Transactions.