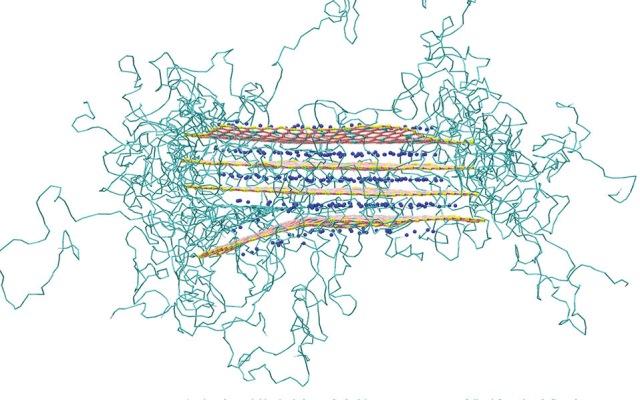

Polymer interacting with clay particles.

Polymer interacting with clay particles.

Scientists at University College London (UCL) have used supercomputer simulations to develop a ‘virtual lab’ for designing new nanocomposite materials. James Suter, Peter Coveney and Deren Groen based in UCL’s Centre for Computational Science have collaborated to develop the ‘virtual lab’.

Nanocomposites are materials composed of microscopic particles dispersed through plastics. The ‘virtual lab’ will help improve the understanding of the molecular level structure of composite materials. Advanced computer simulations will enable the prediction of a new material’s properties based on the method of manufacture and its structure at the molecular level.

“Developing composite materials has been a bit of a trial-and-error process until now,” James Suter (UCL Chemistry), the first author of the study said. “It typically involves grinding and mixing the ingredients and hoping for the best. Of course we test the properties of the resulting materials, but our understanding of how they are structured and why they have the properties they have, is quite limited. Our work means we can now predict how a new nanocomposite will perform, based only on their chemical composition and processing conditions.”

The research team analyzed a composite material that was composed of montmorillonite clay particles and a synthetic polymer. The process that takes place cannot be observed directly because it is smaller than the wavelength of light. Therefore, they cannot be studied using microscopes. Even when less direct methods are used, the clay particle structure prevents observation of the process.

The clay particles are similar to packs of playing cards stacked on top of each other. They are composed of tightly packed sheets that may cleave off completely or separate out, when polymer molecules slide between the sheets. Most of the interaction that occurs between the clay and the polymer is therefore not visible.

Our study developed computer simulations that describe precisely how the layered particles and the polymer chains interact. The challenge is getting enough precision without the computer simulation being unmanageable.

Certain processes need a highly detailed simulation which describes everything on a quantum level – but if we simulated the entire sample at that level, we’d literally need several decades of supercomputer time.

Dr. Derek Groen

Co-Author of the Study - UCL Chemistry

The research team demonstrated that some interactions needed a quantum simulation such as when a polymer chain and the edge of a clay sheet make contact with each other. Certain other interactions need only an atomic level simulation for instance, the representation of each atom in a molecule as a ball on a spring.

Furthermore, other interactions require a lower fidelity level, where atoms are bundled together to provide the approximate properties and shape of a molecule. This endeavor enables a multi-scale approach to modelling of materials. Here, the required level of detail can be considered for various components of the computer simulation.

The computer simulations demonstrated the exact interaction between the clay particles and polymers. The tangled bundle of polymer molecules, which are long and chain-like, unwind themselves and then slip in between the clay particle sheets. Some types of polymers can gently persuade them to separate.

When you make approximations like this, it’s important to test that they are accurate. A lot of our work involved comparing the different types of simulation and ensuring that they gave results that were consistent with each other.

The quantum mechanical model starts from first principles and is derived from the most basic laws of physics, so we know it’s right. But there are quite a few assumptions involved in a molecular model, and we had to ensure those assumptions were correct.

James Suter

Author of the Study - UCL Chemistry

Polymer-entangled clay sheets aggregated into organised arrays of stacks and demonstrated very different properties. The multi-scale simulations also allowed analysis on longer timescales and length. Here, the researchers were able to observe this aggregation. The predictions observed in this study, are being used for improving creation of composite materials.

Multiple high-performance computing facilities were required for performing these simulations. The ARCHER supercomputer in Edinburgh, UK, and the BlueJoule and BlueWonder supercomputing facilities at STFC’s Daresbury Laboratory were coordinated for performing these computer simulations. This would have been difficult to achieve five years ago, and not possible a decade ago.

This study entitled 'Chemically Specific Multiscale Modeling of Clay–Polymer Nanocomposites Reveals Intercalation Dynamics, Tactoid Self-Assembly and Emergent Materials Properties' has been published in the Advanced Materials journal.