Dr. George Nelson, an assistant professor of mechanical and aerospace engineering at The University of Alabama in Huntsville (UAH) has been awarded a $502,000 National Science Foundation (NSF) Faculty Early Career Development (CAREER) Program grant to conduct studies into the possibilities of using nanomaterial cathodes for electric car batteries.

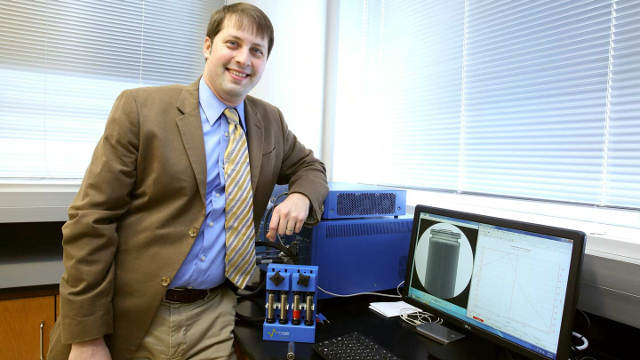

Dr. George Nelson with batteries ready for testing and an x-ray nanotomography result on the computer in his lab at Shelby Center for Technology. (Photo: Michael Mercier | UAH)

Dr. George Nelson with batteries ready for testing and an x-ray nanotomography result on the computer in his lab at Shelby Center for Technology. (Photo: Michael Mercier | UAH)

The outcome of this research could possibly lead to the creation of electric car batteries which are smaller and lighter, without compromising on durability. Creation of batteries of smaller sizes would be possible only with nanomaterials.

Nanomaterials may pave the gap between compact size and increased battery power more favorable when compared to the increased temperature variations that cars and other devices are subjected to.

There have been a number of studies that have documented the variations in battery lifetime caused by variations in temperature.

For example, by parking your electric car in the sun instead of the shade, you could be significantly shortening the life of its battery, by perhaps as much as two years. If you lost two years of battery life, that shorter lifespan would be the equivalent of another car payment.

Dr. George Nelson

Dr Nelson said that this amount of money could have a significant impact when multiplied over the marketplace. One approach to mitigating this is to increase the size of the battery used by 10 to 20%. However, this increases the usage of rare materials such as lithium, which adds to the cost of the vehicle and creates environmental impacts through increased waste and resource depletion.

To address these issues, scientists at the UAH are working on synthesizing nanomaterials for alternative cathode materials at the College of Engineering's Transport Reaction and Energy Conversion (TREC) Lab at the Shelby Center for Technology. They want to comprehend how nanomaterials might impact the dependability of the battery's cathode at elevated operating temperatures, the cathode being the positive terminal of the battery.

Generally, cathodes are constructed using larger materials on the micron-size scale that connect more freely than the smaller nanomaterials.

There are a lot of people pursuing nanoscale battery materials. The benefit of nanomaterials is that they have much greater surface area for the chemical interactions that create electric current, resulting in more power for their size. But that also can be a drawback when it comes to lifespan over a wide temperature range.

We suspect that increased temperature will shorten battery life for these materials, more so than traditional materials.

Dr. George Nelson

The UAH scientists are testing batteries made with different cathode compositions by charging and discharging them at different temperatures and observing the alterations in the cathode structure using X-ray nanotomography. The test results would help to pinpoint which higher-power nanomaterial possesses the maximum duration.

Dr. Nelson's research is conducted in partnership with the Texas A&M University using the Advanced Photon Source, a synchrotron at Argonne National Laboratory in Lemont, Ill. The partnership with Texas A&M is primarily to study closely the interactions between microstructure and lithium transport in new anodes for lithium-ion batteries. The anode is basically the negative terminal of the battery.

The two research projects have received wide recognition and invitations to conduct additional research the lab facilities at Stanford University.

I was very, very fortunate to win the CAREER award and an NSF Collaborative Research grant to support our battery research. It's a once in a lifetime opportunity, and I look forward to making the most of it.

Dr George Nelson

The CAREER grant's educational and outreach programs also supports a battery experiment sequence for the Undergraduate Heat Transfer Lab. It will soon be linked with the teacher training provided by the U.S. Space & Rocket Center.

You can read more about research at UAH here.