Feb 19 2015

Scientists at Bourns College of Engineering of the University of California, Riverside (UC Riverside) have created a new material for lithium-ion batteries that contains sponge-like silicon nanofibers.

The paper-like material is more than one hundred times thinner than a human hair and could significantly improve the specific energy or the quantity of energy that can be supplied per unit weight of a lithium-ion battery. This latest breakthrough has the potential to be used in a number of applications including batteries for personal electronics and electric cars.

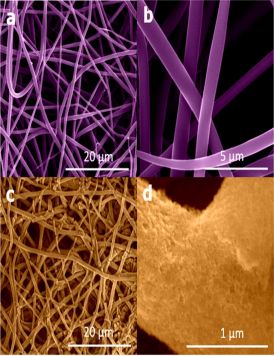

Scanning electron microscope images of (a) SiO2 nanofibers after drying, (b) SiO2 nanofibers under high magnification (c) silicon nanofibers after etching, and (d) silicon nanofibers under high magnification.

Scanning electron microscope images of (a) SiO2 nanofibers after drying, (b) SiO2 nanofibers under high magnification (c) silicon nanofibers after etching, and (d) silicon nanofibers under high magnification.

The paper entitled ‘Towards Scalable Binderless Electrodes: Carbon Coated Silicon Nanofiber Paper via Mg Reduction of Electrospun SiO2 Nanofibers’ has been published in the journal Nature Scientific Reports. Authors include Cengiz S. Ozkan, a professor of mechanical engineering, Mihri Ozkan, a professor of electrical and computer engineering, and their graduate students Rachel Ye, Zach Favors, Kazi Ahmed, Hamed Hosseini Bay, Robert Ionescu, and Zafer Mutlu.

The researchers produced nanofibers by using an electrospinning technique, wherein 20,000-40,000 volts was applied between a nozzle and a rotating drum. This nozzle releases a solution that primarily contains tetraethyl orthosilicate (TEOS), a kind of chemical compound that is often used in the semiconductor industry. The nanofibers were then exposed to magnesium vapor to create the silicon fiber structure.

Lithium-ion battery anodes are traditionally developed using a copper foil, which in turn is coated with a mixture of a polymer binder and graphite, a conductive additive. Since graphite’s performance is virtually known, scientists are exploring other materials such as silicon, which exhibits an electrical charge per unit weight of the battery or specific capacity that is almost ten times that of graphite.

However, silicon tends to undergo a considerable volumetric expansion, which can rapidly deteriorate the battery. The sponge-like silicon fiber structure produced by the researchers overcomes this problem and enables the battery to be cycled countless of times without any major degradation. In addition, this technology solves the scalability factor associated with free-standing electrodes.

Free-standing or binderless materials grown by using chemical vapor deposition, such as silicon nanowires or carbon nanotubes, can only be created in small amounts. Nevertheless, Favors successfully created several grams of silicon nanofibers at a single time.

Eliminating the need for metal current collectors and inactive polymer binders while switching to an energy dense material such as silicon will significantly boost the range capabilities of electric vehicles.

Zach Favors - graduate student at Bourns College of Engineering

The scientists are planning to integrate the silicon nanofibers inside a lithium-ion battery having a pouch cell format, which is a larger scale battery format that can be utilized in portable electronics and electric vehicles.

Patents have been filed by the UC Riverside Office of Technology Commercialization for inventions reported in the study paper. The study was supported by Temiz Energy Technologies.