The European HiPoSwitch project has developed novel nitride (GaN) transistors for high efficiency, high speed gallium nitride power switches.

The project is led by the Ferdinand-Braun-Institut, Leibniz-Institut für Hoechstfrequenztechnik in Berlin, in collaboration with eight industrial and research partners from across central Europe.

GaN components are very efficient and very fast power switches... because of their low on-state resistance with negligible losses. Further, the power converter’s higher switching frequencies allow its passive elements to be smaller in size.

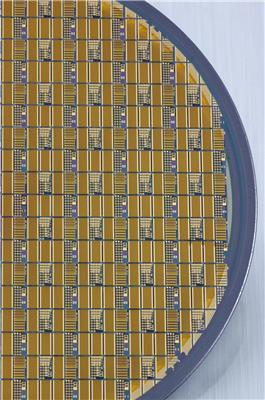

Basis for energy-efficient and compact power converters: gallium nitride switching transistors on silicon substrate developed within the HiPoSwitch project. (c) FBH/P. Immerz

Basis for energy-efficient and compact power converters: gallium nitride switching transistors on silicon substrate developed within the HiPoSwitch project. (c) FBH/P. Immerz

Lightning-fast power switches are needed to make power convertors which are compact, light-weight and energy-efficient. These converters are widely used in many electronic devices, so any new design which offers effiency benefits will have a huge market potential.

Most electronic devices, including computers, smartphones and led lighting, cannot accept normal line voltage, unless it is converted from AC to DC. In solar panel inverters, and other such devices, the reverse is needed, to convert the DC current generated by the solar panels into AC power. Power transistors are a crucial part of the power converters that perform these conversions.

As part of the HiPoSwitch project, lightning-fast semiconductors switches have been developed that allow more efficient operation of these types of converters. The new power converters that use novel gallium-nitride transistors enable more than 98% conversion efficiency, and demonstrate less than 50% of the losses compared to conventional silicon. Usage of these transistors will help save significant amount of primary energy.

Joachim Würfl, head of both the HiPoSwitch project and the GaN Electronics Business Area at FBH, explains:

“More than 3000 terawatt-hours of power are generated in Europe annually. If you only converted a quarter of the electricity produced annually in Europe to a different level and increased the efficiency level by two percentage points, you can turn off at least two coal-fired plants.

"GaN components are very efficient and very fast power switches... because of their low on-state resistance with negligible losses. Further, the power converter’s higher switching frequencies allow its passive elements to be smaller in size. These elements include its capacitors and inductive coils.

"GaN has been used as thin layers on silicon carbide (SiC) substrates and in microwave transistors. This works well, but it is too expensive for mass markets.

"As an alternative, the processes developed for SiC can be transferred to considerably more cost-effective, but technologically more challenging silicon substrates."

The Ferdinand-Braun-Institut. © FBH/schurian.com

Collaboration from materials research to systems manufacturing

The progress made on the project is a result of the perfect fit between the developments achieved by each partner. The University of Vienna and the University of Padua conducted the original studies on the effects of degradation and drift, which allowed FBH to optimize the process for creating GaN switches to such an extent that the components' performance almost matches the theoretical ideals.

Infineon in Malaysia then performed the final assembly of the transistor chips into low-induction ThinPAK housings. The epitaxy was moved to Si by Aixtron, a facility manufacturer, and EpiGaN, a Belgian company. This led to significant reduction in substrate manufacturing costs that was in the range of more than a factor of ten.

The wafer diameter was increased to 6" and also to 8", which would contribute to cost-effective production on the industrial scale. Infineon, a chip-manufacturer, offered a Si process line for production of power semiconductors at the industrial scale.

The single transistor measures only 4.5 x 2.5 mm and is optimized for switching 600 volts. It has an on-resistance of 75 milliohms and handles a maximum of 120 amperes. We are the only ones in Europe who can manufacture these kinds of normally-off transistors at present.

Joachim Würfl

Würfl states that certain parts of the project had an “exploratory character”, due to the novel processes and techniques that were used for implementing GaN power transistors. Methods that held promise for production of semiconductors were tested at the Academy of Sciences in Bratislava, Slovakia, and at the University of Vienna.

Artesyn, an Austrian company, is a systems-level partner in this collaboration. Artesyn developed a 3kW rectifier designed for cellular base stations, and other such telecommunications applications. This rectifier has the capability to convert line voltage to DC with 98% efficiency. A switching topology that matched the GaN switching transistors’ properties was developed.

Energy-saving power converters have a huge market potential as they are widely used. They are also preferred for aerospace applications due to their low weight and smaller size.

For more information on this project, visit the HiPoSwitch website.