Apr 21 2015

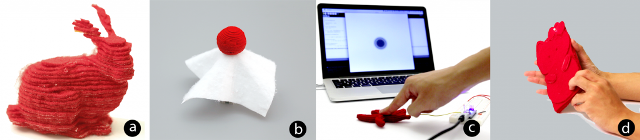

3D printed objects from our layered fabric 3D printer: (a) printed fabric Stanford bunny, (b) printed Japanese sunny doll with two materials, (c) printed touch sensor, (d) printed cellphone case with an embedded conductive fabric coil for wireless power reception.

3D printed objects from our layered fabric 3D printer: (a) printed fabric Stanford bunny, (b) printed Japanese sunny doll with two materials, (c) printed touch sensor, (d) printed cellphone case with an embedded conductive fabric coil for wireless power reception.

A collaborative team of researchers belonging at Disney Research and Carnegie Mellon University have developed a 3D printer capable of making layers of laser-cut sheets made from a fabric to create soft, squeezable objects such as bunnies, phone cases and doll clothing.

It is possible to build these objects with complex geometries and even integrate circuitry into them thereby rendering them interactive.

"Today's 3D printers can easily create custom metal, plastic, and rubber objects," said Jim McCann, associate research scientist at Disney Research Pittsburgh. "But soft fabric objects, like plush toys, are still fabricated by hand. Layered fabric printing is one possible method to automate the production of this class of objects."

The fabric printer uses a technique quite as same as laminated object manufacturing, where paper or metal sheets cut into a 2D shape are bonded together so as to form a 3D object. Cutting and handling of fabric can prove to be quite challenging, but the Disney research team has incorporated some remedies into the design of their printer.

The working of the layered-fabric printer will be explained at the Association for Computing Machinery's annual Conference on Human Factors in Computing Systems, CHI 2015, April 18-23 in Seoul, South Korea. The research has already received an honorable mention for a Best Paper award.

Apart from McCann, the team also consisted of Huaishu Peng, a Ph.D. student in information science at Cornell University, and Scott Hudson and Jen Mankoff, faculty members in Carnegie Mellon's Human-Computer Interaction Institute.

The year before, Hudson showcased a soft 3D object printer at CHI which he built at Disney Research. It was capable of depositing layers of needle-felted yarn. In contrast the layered-fabric printing technique is capable of creating thicker as well as much more squeezable objects.

The novel soft printing device consists of two fabrication surfaces, namely, a lower bonding platform and an upper cutting platform. The device is loaded with the fabric from a roll. The fabric is help up against the upper cutting platform with the aid of vacuum and at the same time a laser cutting head moves underneath.

A rectangular piece of fabric is cut by the laser from the roll. Next the laser cuts the rectangular piece into the desired 2D shape or shapes. The second cutting step is not fully completed, thereby enabling the shapes to be supported by the surrounding fabric during the fabrication method. When the cutting is done, the bonding platform is elevated up to the fabric and the vacuum is cut off, thereby freeing the fabric.

Next the platform is brought down and a heated bonding head is turned on to heat and press the fabric against preceding layers. The bonding method involves the fabric being coated with a heat-sensitive adhesive just like in the case of applying non-stitched fabric ornamentation onto a banner or outfit using a hand iron. On completion of this method, the surrounding support fabric is manually cut away by hand to expose the 3D object.

For their research, the team used 32 layers of 2mm-thick felt to design a 2 ½-inch bunny. The entire operation was completed in around 2 ½ hours. "The layers in the bunny print are evident because the bunny is relatively small compared to the felt we used to print it," McCann said. "It's a trade-off -- with thinner fabric, or a larger bunny, the layers would be less noticeable, but the printing time would increase."

It is possible to use two types of material to design one object. One roll of fabric can be supplied into the machine from left to right while another roll of a different material can be supplied front to back. In case one material is conductive, adequate wiring can be added into the device.

The researchers illustrated how it is also possible to design a fabric starfish which can act as a touch sensor as well as a fabric smartphone case with an antenna capable of collecting adequate energy from the phone to light up an LED.

During the fabrication method, feel of the object can be achieved by adding small cuts on the inner sides to allow easy bending of the object in one direction and at the same time preserving the stiffness in the perpendicular direction.