May 19 2015

Researchers at the Technische Universität München consider that a new approach that involves a combination of 3D-printed microfiber scaffolding and hydrogels holds promise for more effective usage of biocompatible materials for repairing human tissues.

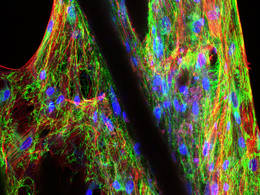

Confocal laser microscopy of a scaffold populated with human mesenchymal precursor cells. Image Credit: D. Hutmacher | QUT

Confocal laser microscopy of a scaffold populated with human mesenchymal precursor cells. Image Credit: D. Hutmacher | QUT

An international team of researchers conducted a study on restoring cartilage. Cartilage requires both mechanical strength and flexibility.

The research team analyzed and tested composite materials that demonstrated stiffness and elasticity that could be considered equivalent to that possessed by knee-joint tissue.

These materials were also tested for their ability to aid growth of human cartilage cells, as well as their cross-linking ability. The new technique could benefit heart tissue engineering, breast reconstruction and other types of applications requiring soft-tissue engineering.

The new melt electrospinning 3D printing technique provided the necessary mechanical stiffness, and also the room required for cell growth.

Prof. Dietmar W. Hutmacher, who is one of the lead authors of the study, states that, this innovative method places less restrictions in designing the scaffolding that would contribute to healing of damaged tissue and new tissue growth. At the TUM Institute for Advanced Study (IAS), Prof. Hutmacher is a Hans Fischer Senior Fellow.

"It allows us to more closely imitate nature's way of building joint cartilage," he says, "which means reinforcing a soft gel – proteoglycans or, in our case, a biocompatible hydrogel – with a network of very thin fibers."

When compared to conventional methods for creating scaffolding filaments, the melt electrospinning method can help produce scaffolding filaments that have a diameter as small as 5µm, and this is 20 times better in comparison.

TUM Prof. Arndt Schilling hosts Prof. Hutmacher’s TUM-IAS Focus Group. At TUM's university hospital Klinikum rechts der Isar, Prof.Schilling heads the Research Dept. of Plastic Surgery and Hand Surgery.

Researchers from the UK, Australia, the Netherlands, and Germany, who collaborated in this research, utilized a wide range of tools for this study. While conducting tests on the hydrogel-fiber composites, they simultaneously compared it with computational simulations, equine knee-joint cartilage and human cartilage cells growth in artificial matrix.

Hutmacher considers this to be a possible breakthrough. The research team is assessing the possibility of utilizing these hydrogel-fiber composites for other possible applications, following the validation of its computer model.

"The new approach looks promising not only for joint repair, but also for uses such as breast reconstruction following a post-tumor mastectomy or heart tissue engineering,"

"We need to implant the scaffolding under the muscle, and fiber-reinforced hydrogel could prove critical in regenerating large volumes of breast tissue, as well as the biomechanically highly loaded heart valves."

The novel approach that has been published as a paper in the Nature Communications journal is being considered for breast tissue engineering research by Prof. Arndt Schilling, Dr. Elizabeth Balmayor and Dr. Jan-Thorsten Schantz of TUM and Prof. Hutmacher. This group is also collaborating with Dr. Petula Mela and Prof. Stefan Jockenhövel of the RWTH Aachen, on a study on engineering heart valve tissue.

This study has been published as a paper titled, 'Reinforcement of hydrogels using three-dimensionally printed microfibers' in the journal Nature Communications.