Researchers at the Institute for Basic Science (IBS) Center for Integrated Nanostructure Physics at Sungkyunkwan University (SKKU) in South Korea have developed a new semiconductor material from black phosphorus (BP), which holds promise as a replacement for silicon in future computer chips. Director Young Hee Lee led part of this study.

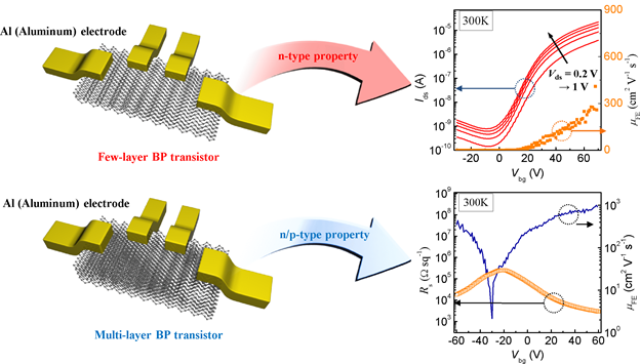

Atomic structure of black phosphorus and n/p-type transistor property of BP transistor

Atomic structure of black phosphorus and n/p-type transistor property of BP transistor

In the 1980’s, numerous computer chip manufacturing companies had sprung up in Northern California, which led to the area being named as Silicon Valley. Silicon is a vital, omnipresent material in computer chips. However, a new version of black phosphorus may provide some competition to silicon.

Materials demonstrating semiconducting properties are used to fabricate transistors of two types - n-type and p-type. n-type transistors have excess electrons, while p-type transistors have excess holes. In this study, the team discovered that they could modify the thickness and/or the contact metals of black phosphorus (BP) crystal. This determines whether the crystal would function as a p-type, n-type, or ambipolar material. An ambipolar material is one that can work as n- or p-type material.

In order to make silicon as n-type or p-type, it needs extrinsic doping. This requires another element to be inserted into its crystal structure. However, BP crystals do not require extrinsic doping to function as both n-type and p-type, or as a material that is something in between. This would enable a transistor to be made with a single pure black phosphorus logic chip without doping, in place of using silicon-arsenic crystal that is sandwiched between crystals of silicon-boron.

Furthermore, the n- or p-type of BP can be determined by changing the metals that are used for connecting the circuit and the chip. In this case, doping is not required, and both the n- and p-type BP can be put on a chip by modifying the contact metal and the thickness.

Technology manufacturers are trying to make their devices smaller, lighter and more efficient. Transistors can be made using BP that is just a couple of atomic layers thick.

The threshold for size of silicon chips in electronic devices is being reached, and BP may hold promise as a thinner and more efficient material for electrical devices.

The Internet of Things (IoT) is made up of very small, autonomous devices for recording of data and transmission. The inability of the industry to further reduce the size of the components, as well as the lack of a long-term power solution, has been a major deterrent in adoption of IoT. BP and other such 2D layered materials hold promise as they have better mechanical and electrical properties when compared to 3D materials.

BP material has high carrier mobility, which is very advantageous for transistors. This property would enable BP to function better even at lower voltages, which would in effect lead to lower power consumption.

When BP flakes of 13 nm thickness are used with aluminum as the contact material, they demonstrate ambipolar properties similar to those demonstrated by graphene. However, thin 3 nm BP flakes are unipolar n-type and they possess more than 105 switching on/off ratios. The switching performance increases as the thickness of the material decreases.

SKKU research fellow David Perello explains, “The driving force in back phosphorus is the carrier mobility. Everything centers around that. The fact that the band gap changes with thickness also gives us flexibility in circuit design. As a researcher it gives me a lot of things to play with.”

However, a good method for large scale production of pure BP is not yet available, while methods for large scale production of other industry standard semiconductor materials are available. The only method available now to produce thin layers of BP is by scraping bulk samples of crystalline BP. Other researchers are addressing scaling issues by using thin film growth techniques such as chemical vapor deposition (CVD). However, Perello explains, “We can probably operate with 3, 5, or 7 layers and that might actually be better in terms of performance.”

When Perello was questioned whether BP could compete with silicon in its present stage today, he said, “I don’t think it can compete with silicon at the moment, that’s a dream everybody has. Silicon is cheap and plentiful and the best silicon transistors we can make have mobilities that are similar to what I was able to make in these BP devices.”

This doesn’t mean that BP isn’t worth exploring further though. According to Perello, “The fact that it was so simple to make such an excellent transistor without having access to state of the art commercial growth, fabrication and lithography facilities means that we could make it significantly better. We expect the upper bound for carrier mobility in black phosphorus to be much higher than silicon.”

The potential of BP is just being recognized and it is not quite ready for commercial applications. It could challenge other chip material for future applications if it performs well in further tests.