Ettlinger Kunststoffmaschinen will take advantage of this year's Fakuma to show its complete range of high performance melt filters, designed for continuous processing of any kind of feedstock from virgin material to heavily contaminated recycled plastic.

Ettlinger's ECO melt filters, only recently launched in the market, have been specially developed for film and sheet extrusion. Rated for a maximum contaminant level of 1.5% by weight, they enable cross-linked and high-molecular fractions contained in the melt to be efficiently removed when processing virgin material along with any gels or partial impurities. The merits of the ERF melt filter series, already proven in over 225 installations, are particularly powerful when it comes to heavily contaminated feedstock. Reliable, pressure-stable, continuous processing is guaranteed with up to 18% contamination by weight. The ERF series of melt filters are perfect for even difficult applications like converting post-consumer waste. The ERF500 is the largest of the family and is capable of throughputs up to a maximum of 6 tons per hour. It is also the newest addition to the ERF filter family.

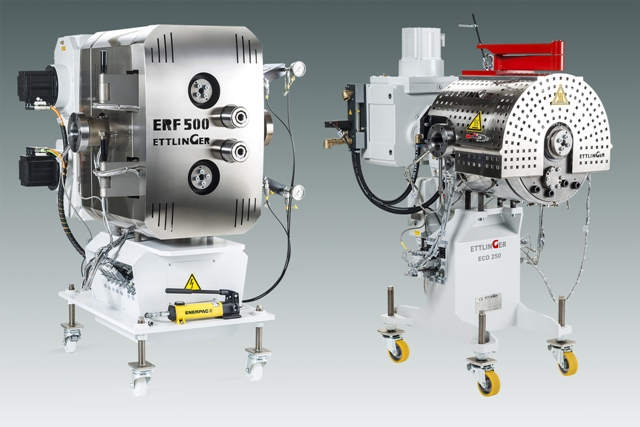

Designed for a wide range of melt filtration applications: ERF high performance filters for heavily contaminated polymer feedstock with up to 18% by weight contamination (on the left in the photo, the ERF 500 size for a maximum throughput of 6 t/h) and ECO melt filters, developed for film and sheet extrusion using virgin material with up to 1.5% by weight contamination (on the right, the ECO 250 for throughputs up to 3 t/h). Photos: Ettlinger

Designed for a wide range of melt filtration applications: ERF high performance filters for heavily contaminated polymer feedstock with up to 18% by weight contamination (on the left in the photo, the ERF 500 size for a maximum throughput of 6 t/h) and ECO melt filters, developed for film and sheet extrusion using virgin material with up to 1.5% by weight contamination (on the right, the ECO 250 for throughputs up to 3 t/h). Photos: Ettlinger

ECO melt filters come in two different sizes: the ECO 200 for throughputs up to 1000 kg/h and the ECO 250 can process up to 3000 kg/h. In addition to the "standard" ECO model, this filter can also be supplied as a PET version for filtering very easy-flowing melts such as polyester or polyamide. Ettlinger ERF filters are offered in three sizes; in addition to the new ERF 500, an ERF 250 with a maximum throughput of 3 t/h and an ERF 200 which can process up to 1 t/h are also available.

One key feature of both filter series is that they are built to last. Whereas conventional piston screen changers can require many screen changes per day, each one causing the filtration process to be interrupted, both the ECO and the ERF achieve a trouble-free service life of several weeks with no disruptions to production. The investment in an ECO or ERF filter thus pays for itself very quickly, not least owing to the extremely low melt losses. The screen of both filter types remains open throughout the production phase to permit absolutely stable processing with a constant volume and pressure. With their compact, space saving design they can be retrofitted in existing extrusion lines without any problems.

Designed for high process stability

The central component of the ECO and ERF melt filters is a rotating, cylindrical filter screen with millions of conical holes that can be supplied with a wide variety of ratings. When melt flows through these filters, contaminants are retained on the outside of the screen while the cleaned melt on the inside of the drum travels to the downstream pelletizing machine or mold via a system of flow channels. The rotary motion of the filter drum simultaneously supports the blending effect and ensures optimal homogeneity in the melt.

With every revolution the slowly rotating filter screen, which is driven by a servo motor, is cleaned by a scraper. The particles that are removed from the surface of the screen are continuously fed to a discharge system, driven by a second servo motor, which discharges them from the filter. Not only are solid contaminants like wood and aluminum particles or paper efficiently separated but also gels and the high-molecular and cross-linked fractions which arise due to high temperature stresses.

Ettlinger Kunststoffmaschinen GmbH was founded in 1983 and is today a global player. The German company has its headquarters in Königsbrunn, not far from Augsburg. A sales and service subsidiary opened in Atlanta (Georgia) in 2013. The core competency is the development and manufacture of injection molding machines and high performance melt filters. On the melt filtration side Ettlinger makes systems for continuous filtration of feedstock with varying degrees of contamination. Contaminants like paper, aluminum, wood, silicones, or high-melting polymer composites can be removed from all standard polymer materials. Ettlinger injection molding machines are optimized for the production of polymer moldings up to 100 kilograms in weight such as plastic pallets, fittings, or manholes.