Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, reports on the use of the CT5000 tensile/compression stage at the Centre for X-ray Tomography at Ghent University in Belgium where it is used for tensile and compressive strength tests on geomaterials.

Professor Veerle Cnudde leads the PProGRess team (Pore-scale Processes in Geomaterials Research), one of the co-founding groups of the UGCT. They combine conventional research techniques (e.g. optical microscopy, SEM-EDX, XRD,…) and non-destructive techniques (e.g. high resolution X-ray Computed Tomography) to investigate dynamic processes in geomaterials, related to different research fields, such as fluid flow behaviour; fracture nucleation and propagation in rocks; carbonatation; dissolution, precipitation and crystallization processes in porous stones.

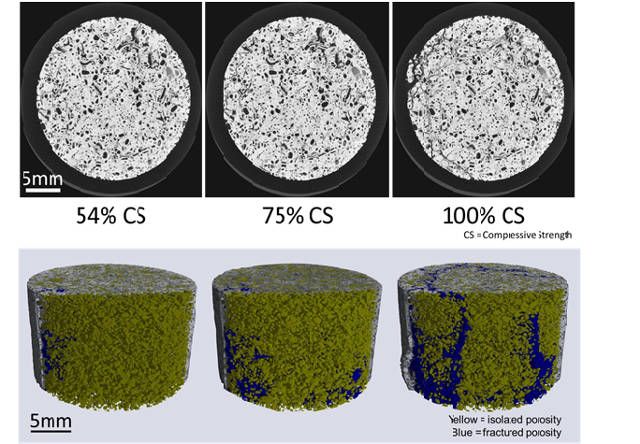

Rock specimens under increasing compressive load.

Rock specimens under increasing compressive load.

Generally speaking, the PProGRess group has the drive to understand the pore scale processes inside geomaterials in order to comprehend and model the macroscopical behaviour in rocks. The Deben CT5000 tensile/compression stage not only offers the possibility to combine tensile and compressive strength tests with the X-ray CT scanners available at the UGCT, it also allows the investigation of freeze-thaw effects on rock samples and the effects of crystallization of salts through the temperature controlled set-up. In combination with the latest environmental X-ray micro-CT scanner (the EMCT software, developed in collaboration with one of their spin-off companies (XRE), it allows for 4D analysis of these processes with both high spatial and temporal resolution.

Asked why she chose to use the CT5000, Professor Cnudde said “The CT5000 system is one of the few systems which are highly adaptable to the needs of individual test cases. It allows different set-ups to be made according to the requirement of the experiment. Important in our research is that it can reach the high loads necessary for rock samples to be broken. Also, the possibility to have a custom made cell (in which the distance between the two jaws was altered to our needs), fitting on two of the scanners at UGCT was one of the decisive points why we chose for the CT5000 system.”

Continuing, she said “Before we had the CT5000 system, we only performed standardized mechanical tests on (large) samples in the laboratory. Now, we can perform these tests in situ, however, limited in sample size but allowing a direct relation with the compression values and the internal structural changes. Other mechanical testing devices we investigated, before we found the CT5000 system, were limited in the load which could be applied on the samples. Because we are mainly working on rock specimens, we really needed a load up to 5000 N to perform compressive and/or tensile tests.”

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk. The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.