DELO Industrial Adhesives has released three new, highly flexible acrylates especially for sealing and casting small-volume applications such as relays, microswitches, and pins. The adhesives combine opposing properties: they are highly flexible, and yet at the same time resistant to temperatures.

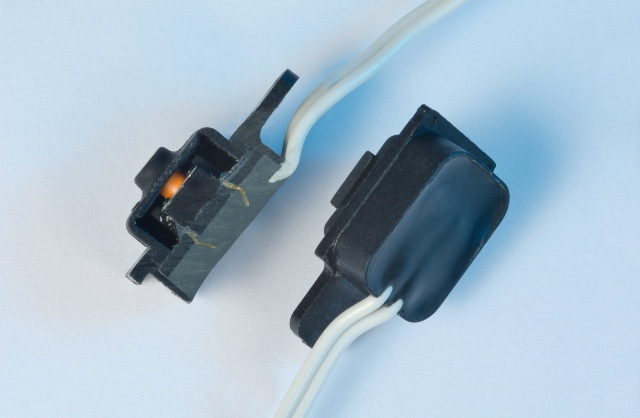

Switch casting for door handles in the automotive field (image: DELO)

Switch casting for door handles in the automotive field (image: DELO)

Previous acrylates from DELO won plaudits particularly for their speed. They fully cure within seconds, enabling fast production processes and a high yield rate. In addition, the adhesives have a universal adhesion, are highly flexible, and balance tension. Their temperature limit is 120 °C.

Things are different with the new sealants. In addition to the existing benefits, they have taken a considerable leap in temperature, and retain their flexibility even at temperatures of up to 150 °C. This can be clearly seen with a constant Young’s modulus, as even after 1,000 hours of temperature storage at 150 °C it remains low.

In addition, the acrylates have excellent sealing properties, as is demonstrated during a thermal shock test from -40 °C through 150 °C. The products exhibit full leak-tightness here, even after 300 cycles. These are important criteria, particularly for bondings in the automotive field.

The right sealant for each application

The new sealants are the purely light-curing DELO-PHOTOBOND GE4009, the light- and heat-curing DELO-DUALBOND GE4707, and the light- and moisture-curing DELO-DUALBOND GE4906. Both dual-curing adhesives are particularly suited to applications with shadow areas.