Researchers from Massachusetts Institute of Technology (MIT), Xi’an Jiaotong University and Carnegie Mellon University amongst others have discovered that when nanoscale metal pieces are stretched in small amounts repeatedly, the material can be strengthened as crystal defects are eliminated. This new process is known as “cyclic healing.”

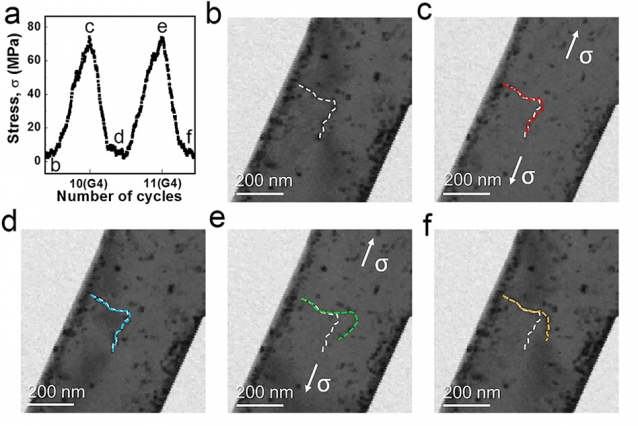

This image shows abrupt de-pinning and de-stabilization of a line defect due to repeated cyclic loading. Figure (a) shows the evolution of nominal tensile stress during two loading and unloading cycles. Figures (b) to (f) are still frames from a video that correspond to the stress state marked in (a), where the white dashed lines indicate the original defect location, and the colored dashed lines represent the altered locations from cyclic loading. The direction of tensile stretching is indicated by the arrows in figures (c) and (e). Image: Zhangjie Wang, Zhiwei Shan, Ming Dao, and Subra Suresh

This image shows abrupt de-pinning and de-stabilization of a line defect due to repeated cyclic loading. Figure (a) shows the evolution of nominal tensile stress during two loading and unloading cycles. Figures (b) to (f) are still frames from a video that correspond to the stress state marked in (a), where the white dashed lines indicate the original defect location, and the colored dashed lines represent the altered locations from cyclic loading. The direction of tensile stretching is indicated by the arrows in figures (c) and (e). Image: Zhangjie Wang, Zhiwei Shan, Ming Dao, and Subra Suresh

When metals are bent repeatedly in the same place, the material can become weak and break due to metal fatigue. When metal components undergo repeated stress, they could get damaged due to metal fatigue.

“While metal fatigue has been studied extensively at larger volumes of materials, there has been little understanding of it at atomic scale,” says Dao, a principal research scientist in MIT’s Department of Materials Science and Engineering.

The research team decided to use transmission electron microscopy to study the atomic-scale changes that took place in the crystal defects of small, single, aluminum crystal pieces. The microstructural imperfections are also known as “dislocations.” The researchers attempted to eliminate or decrease microstructural imperfections using cyclic deformation of small amplitude without relying on the commonly used heat-based annealing process.

When repeated, small displacements of the metal nudged these dislocations out of the location that they are stuck in within the crystal. These dislocations were attracted to the surface as the small crystal demonstrated high surface to volume ratio. Additionally, the energy stored in the metal due to the defects could also be reduced. “Eventually, these defects can be driven all the way out to the surface,” Dao says.

Gentle, repeated 'shaking' of the dislocations could free the material of them, and increase the strength of the material. This process is exactly the opposite of that observed in comparatively large metal crystals. In large crystals, repeated stretching leads to increase in defect density and crack formation.

The innovative process developed by the team could help manufacture strong parts for various nanotechnology applications, including nanorobots, nanoelectromechanical systems, and mechanical nanosensors.

“This work demonstrates how cyclic deformation, under certain controlled conditions, can lead to the removal of defects from crystals of small volume,” says Suresh, Carnegie Mellon’s president and a professor emeritus of materials science and engineering and former dean of engineering at MIT. “In addition to pointing out how these mechanisms of cyclic deformation can be very different from those seen in larger-volume materials, this work also offers new avenues for eliminating defects from crystals without the need for thermal treatment or shape change.”

Julia Greer, a professor of materials science, mechanics, and medical engineering at Caltech, who was not involved in this work, says that while the basic underlying phenomenon of removing defects through deformation was already known, “what’s new here is that the authors demonstrated that you can elicit this phenomenon by conducting cyclical deformation, which does not plastically change the shape of the metal yet eliminates the defects, and hence requires greater applied forces to deform/fail it. So in the end you get a more pristine metal, which contains virtually no defects, and because of it is very strong.”

The study paper has been published in the Proceedings of the National Academy of Sciences.

The co-authors of the paper are Ming Dao and Ju Li of MIT; Subra Suresh of Carnegie Mellon; Zhiwei Shan of Xi’an Jiaotong University; researchers at Johns Hopkins University, and others from China.

The National Science Foundation, the U.S. Department of Energy, the 973 Programs of China, and the Singapore-MIT Alliance for Research and Technology supported the study.