Jan 19 2016

3D printing techniques are currently used to design and build components in a rapid manner. A new technique, developed by an engineering team from the University of Bristol, allows printing of composite materials. These materials are utilized in a number of high performance products, including airplanes, golf clubs, and tennis rackets. This new technology will also allow for a wider range of things to be 3D printed at home.

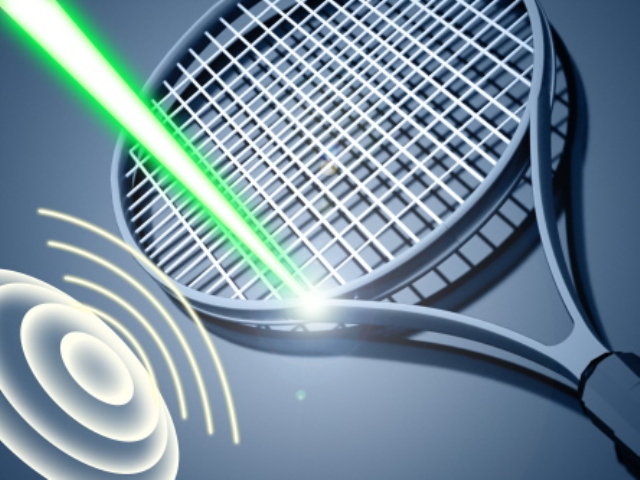

The research team have developed the first demonstration of 3D printing of composite materials. Ultrasonic waves produce a pattern of microscopic glass fibres which give the component increased strength. A laser cures the epoxy resin and creates the component. (Credit: Image courtesy of Matt Sutton, Tom Llewellyn-Jones and Bruce Drinkwater © 2016)

The research team have developed the first demonstration of 3D printing of composite materials. Ultrasonic waves produce a pattern of microscopic glass fibres which give the component increased strength. A laser cures the epoxy resin and creates the component. (Credit: Image courtesy of Matt Sutton, Tom Llewellyn-Jones and Bruce Drinkwater © 2016)

The study on this new technology is available in the journal Smart Materials and Structures under the title, “3-D printed components with ultrasonically arranged microscale structure.” Thomas M. Llewellyn-Jones, Bruce W. Drinkwater, and Richard S. Trask are the authors on the paper.

The study exhibits a unique method, using ultrasonic waves to accurately position a huge number of tiny reinforcement fibers as part of the 3D printing process. The fibers form a microscopic reinforcement framework to provide the material strength, a focused laser beam is then used to position this microstructure. Finally, the epoxy resin is cured and the object is printed.

The team demonstrate their system by mounting a focused and switchable laser module on the carriage of a three-axis 3D printing stage, above the ultrasonic alignment apparatus.

We have demonstrated that our ultrasonic system can be added cheaply to an off-the-shelf 3D printer, which then turns it into a composite printer.

Tom Llewellyn-Jones, PhD Student in Advanced Composites

The researchers were able to achieve a print speed of 20 mm/s, which is similar to that of the conventional additive layer techniques. The study highlighted the ability of the technology to assemble a plane of fibers to create a reinforcement framework. Switching the ultrasonic standing wave pattern mid-print enables control of the precise orientation of the fibers.

This method provides evidence of unique fibrous architectures in a 3D printed object. The ultrasonic manipulation technique has a versatile nature, which helps to develop a wide variety of particle shapes, sizes, and materials to be assembled. This results in the creation of a new generation of fibrous reinforced composites, suitable for 3D printing.

Our work has shown the first example of 3D printing with real-time control over the distribution of an internal microstructure and it demonstrates the potential to produce rapid prototypes with complex microstructural arrangements. This orientation control gives us the ability to produce printed parts with tailored material properties, all without compromising the printing.

Bruce Drinkwater, Professor of Ultrasonics, Department of Mechanical Engineering

Dr Richard Trask, Reader in Multifunctional Materials in the Department of Aerospace Engineering, added: “As well as offering reinforcement and improved strength, our method will be useful for a range of smart materials applications, such as printing resin-filled capsules for self-healing materials or piezoelectric particles for energy harvesting.”