Feb 8 2016

UKAEA’s Technology Department has a new arrival - a novel mechanical testing system called ‘MeT1’.

MeT1, manufactured by Phoenix Calibration and Service Ltd, is a bespoke device that will enable rapid mechanical testing of materials at temperatures up to 750°C (pictured right).

The versatile equipment will be used for tensile and fatigue testing as well as a novel technique known as ‘Small Punch' that can be used to measure creep properties and fracture toughness. Creep and fatigue are expected to be the main failure mechanisms for structural materials in a future fusion power plant.

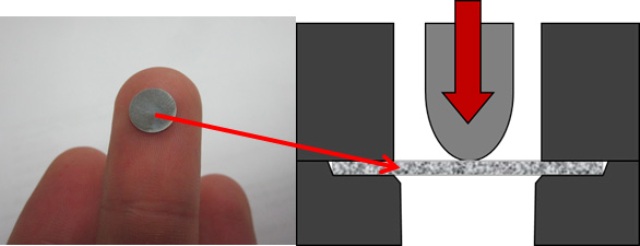

Commenting on the importance of the ‘Small Punch' test, Professor Brad Wynne, Culham-Sheffield University Professor of Materials Technology said: “Small Punch is an exciting new test that works by loading a very small sample until it breaks and then measuring the response.

“This method offers the potential to obtain key materials data from a tiny disk; it's a very exciting development at the edge of our knowledgebase.” [See the illustration below].

Small Punch sample on fingertip (left) and schematic of the test with indenter pressing down on the sample (right).

Small Punch sample on fingertip (left) and schematic of the test with indenter pressing down on the sample (right).

The MeT1 equipment is designed to test millimetre scale samples of the size that would be irradiated in devices such as the proposed device IFMIF (International Fusion Materials Irradiation Facility) that will test the structural integrity of fusion power plant materials under appropriate irradiation damage conditions.

“Understanding the relationship between scale and measured mechanical properties is essential for fusion materials development and the production of engineering standards to build DEMO and fusion power plants,” said Elizabeth Surrey, Head of Technology Department and Technology Programme Manager. “Additionally, being a recent technique, there is an opportunity for UKAEA to drive the development of Small Punch and become world experts. The R&D that this equipment will enable aligns with many of our strategies.”

Although a recent arrival, the new system has already become key equipment within the Technology Department's Materials Testing Laboratory to the delight of Head of the Laboratory, Dr Mike Gorley.

“It is fantastic to see a new state of the art system installed and operational, it's part of a continued effort within UKAEA to have our experimental materials research right at the cutting edge of science and engineering.

"Regarding the Small Punch technique, we are diving right into the deep end by contributing to the global efforts to develop the standard for this technique. This standard will help open up its use in testing irradiated materials and enable us to design new nuclear devices safer, faster and cheaper.”

The new system is already heavily booked by users and is producing valuable data, so expect a big impact from MeT1 and its Small Punch.