Portable, easy to operate Webster testing pliers from Zwick with display of penetration depth which can be converted into Rockwell or Brinell hardness.

Figure 1. Webster pliers

PZ 3

Unique portable device for the performance of standardized, static ball penetration tests according to Brinell up to a max. load of 29420 N. It is possible to carry out hardness tests on materials and workpieces that cannot be tested in the laboratory, e.g. steel stocks, finished constructions, machines, larger metal components. The results correspond to the results obtained with stationary hardness testers.

Figure 2. PZ 3

Sclerograph

Portable hardness testing device for steel and non-ferrous materials. Optionally available:

- Testing anvil for the testing of small test pieces (mass < 1 kg).

- Device for hardness testing on rollers (diameters 100 - 800 mm)

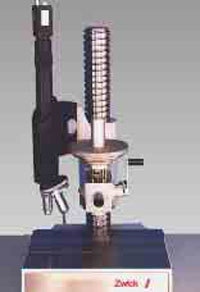

Hardness Tester Zwick 3106

For the testing of the indentation hardness on plastics, Rockwell hardness on metals, plastics and carbon materials as well as the hardness of building plaster and asphalt. It is equipped with a digital dial gauge and can be expanded for the data output on a printer.

Figure 3. Sclerograph

Figure 4. Hardness tester Zwick 3106

Figure 5. Rockwell hardness tester Zwick/ZHR

Rockwell Hardness Testers Zwick/ZHR

The different devices of this product family are designed for

- the classical Rockwell methods (loading : 60 - 150 kg),

- the Super-Rockwell method (loading: 15 - 45 kg) and the

- combination of these methods (loading: 15 - 150 kg).

These devices are distinguished by an indentor mounting support for hardness testing at hardly accessible measuring positions and guarantee a simple and easy operation by

- automatic test mode

- selection of loading weights by rotary type push-button resp. by touchscreen

- automatic loading and unloading

- automatic evaluation including conversion

Additional features:

- preselection of tolerances

- robust construction with backlash free, ball-bearing mounted spindle

- working area up to a height of 292 mm for the testing of large specimens

- RS 232 interface as standard

- manifold standard accessories (indentors, anvils, hardness comparison plates).

- low-cost version with elastic force load application.

Hardness Testers Zwick/ZHV

These Vickers hardness testers cover many different load ranges and have equipments of various comfort levels. Thus, for each case of application customer-specific and suitable devices are available.

Hardness Tester Zwick/ZHV 10

This device is especially approved for the determination of the

- Vickers hardness,

- Knoop hardness,

- Brinell hardness,

- depth of hardness, hardness penetration and nitriding depth as well as

- the scratch hardness (3212001).

Loading weights from 0.2 kg to 10 kg (or to 30 kg) and exchangeable objectives for different magnifications and image ranges are available for both variants:

- With the analog tester (3212001) the hardness value is evaluated by means of hardness tables.

- The PC version (3212003) works with the user software testXpert® which is easy to use and which can be flexibly adapted to changing test conditions. The indentation is measured at the monitor and is evaluated automatically. A Master test program for Vickers, Knoop and Brinell hardness tests is available for series measurements which can be extended for hardness gradient tests and automatic indentation measurement. In addition to manually movable or motorized compound tables, a variety of further accessories as e.g. clamping devices are available.

Vickers Hardness Testers Zwick/ZHV 30 and Zwick/ZHV 50

These devices working in a test load range from 9.8 N to 490 N are used for testing the

- Vickers hardness and the

- Brinell hardness (optional).

They are equipped with dead load weights and an indentor mounting support making them suitable for hardness testing at most flexible test positions and they are supplied with LCD line display or with a touchscreen. The measuring microscope is provided with moveable curtains for the simple acquisition of the indentation diagonal. This value is transferred to the software by pressing a button and the value of hardness is displayed automatically. In addition to the input of tolerance limits, standard-conforming conversions and statistical evaluations are also possible.

Available as standard are RS 232 interface(s) and a large variety of accessories (indentors, anvils, hardness comparison plates).

Figure 6. Vickers Hardness Tester Zwick/ZHV10

Figure 7. Vickers Hardness Tester Zwick/ZHV50

Figure 8. Vickers Hardness Tester ZHV20/Z2.5

Universal Hardness Tester Zwick ZHU/187.5

These devices are designed for hardness tests according to Vickers, Brinell and Rockwell and for different load level combinations. They are easy to operate. The test sequence is carried out automatically. A measuring microscope and a multiline LCD-display are integrated.

The conversion of hardness is also possible. Indentors, hardness comparison plates and specimen tables round off the standard accessories.

Vickers Hardness Testing Machines Zwick ZHV20/Z2.5 and Zwick ZHV30/Z2.5

The hardness testing device for optical measurements is integrated in a Zwick testing machine. The built-in load cell measures electromechanically applied test loads between 2 and 200 N resp. 3 and 300 N. A CCD-camera is fitted on a microscope at an angle of 90°.

Objective lenses and indentor holding device(s) are integrated in the revolver head so that the change of positions between the setting and the measurement of the indentation is carried out by turning the revolver. A Master test program includes series tests according to the methods of Vickers, Knoop and Brinell. Optionally available are extensions for automatic indentation measurements and focusing as well as hardness gradient measurements with manual or motorized compound tables

Universal Hardness Testing Machines ZHU2.5/Z2.5

They can be selected with the installation of the hardness measurement head to a materials testing machine. The hardness measurement head covers all hardness test methods with indentation measurement as e.g.:

- Martens hardness HM (macrorange),

- Rockwell hardness, scales A to K, N, T as well as HMR5/250,

- Ball indentation hardness H,

- Vickers depth measurement HVT and

- Brinell depth measurement HBT.

Integrated in the measurement head are a digital travel measurement system (resolution 0,04 µm), a load cell (ranges: 2 N to 200 N resp. 5 N to 2500 N) and an exchangeable indentor.

The particular features are:

- Simple "1-button"-operation

- Fast and automatic run-up even with different specimen heights

- High accuracy and reproducibility of the test data by high test data resolution and constant test conditions

- Determination of additional characteristic material data from the force-penetration progression

- Suitable for product accompanying tests

A supplementary unit Optics has been developed for the hardness measurement head. This supplementary unit consists of a measuring microscope with up to 4 objective lenses and a linear slide unit to ensure that the component to be tested is not displaced.

The universal hardness testing machine of this combination is – in addition to the above-mentioned test methods – able to carry out standard-conforming hardness tests according to Vickers, Knoop and Brinell. The combination of the supplementary unit Optics and the hardness measurement head leads to extraordinary properties via the testXpert® intelligence. In addition to the known advantages such as automated test sequences and simple adaptation to changing test conditions e.g. the recording of the force-indentation depth sequence is also possible with optical hardness test methods.

The Master test program developed for the hardness measurement head allows to carry out hardness tests according to Martens, Rockwell and ball indentation hardness as well as Vickers and Brinell hardness according to the method HVT and HBT (indentation depth measurement). It is expandable for Vickers, Knoop and Brinell hardness tests. In addition hardness gradient tests with automatic indentation measurement and focusing are also possible.

Figure 9. Universal Hardness Tester Zwick/ZHU187.5

Figure 10. Universal Hardness Testing Machine Zwick ZHU2.5/Z2.5

This information has been sourced, reviewed and adapted from materials provided by ZwickRoell GmbH Co. KG.

For more information on this source, please visit ZwickRoell GmbH Co. KG.