EOS, the global technology and quality leader for high-end Additive Manufacturing (AM) solutions, presents its extensive range of AM solutions for all fields of application – from rapid prototyping to large-scale production – at K 2016 in hall 4 booth B29 from October 19-26.

- From rapid prototyping to large-scale production: Additive Manufacturing solutions for all fields of application

- EOS P 770: Up to 10 percent reduced cost per part and up to 20 percent increased productivity compared to predecessor EOS P 760

- Metal system AM S 290 Tooling: EOS and GFMS enable seamless integration of additive and conventional manufacturing

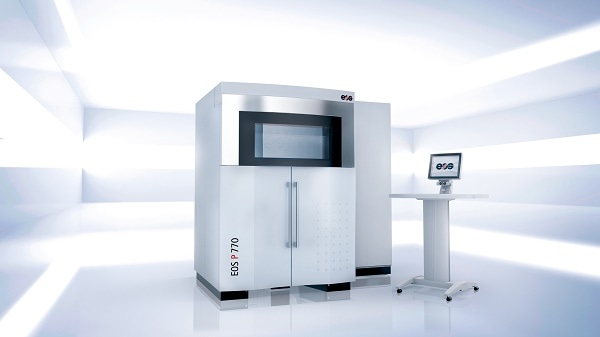

In the area of plastics-based Additive Manufacturing, EOS is presenting the high productivity system EOS P 770 for the first time. The system will build live at the EOS booth.

Thanks to its new hardware and software features, the EOS P 770 is up to 20 percent more productive and can achieve up to 10 percent decreased costs per part than its predecessor.

For the innovative production of mould inserts for large-volume production using injection moulding, EOS together with GF Machining Solutions (GFMS) is presenting the metal system AM S 290 Tooling.

The system is based on the established EOS M 290 system and forms the basis for a seamless integration of additive into conventional manufacturing. The strategic partnership between both companies is a key driver for the further industrialisation in the tooling sector.

The broad range of industrial 3D printing solutions that EOS is presenting at K fair enables companies in the polymer area to master not only the production requirements of today but also the challenges of tomorrow. Highly productive systems for plastic-based Additive Manufacturing, such as the EOS P 770, enable the fast and reliable manufacturing of functional prototypes and serial production. For the production of large-scale series using injection moulding, DMLS solutions by EOS similarly offer distinct benefits in terms of productivity and part quality. This shows that EOS provides the right solution for every application.

Dr. Tobias Abeln, Chief Technical Officer (CTO) at EOS

EOS P 770: Cost-effective production of large plastic parts

The EOS P 770 is a polymer system with two 70 W lasers used for the production of large parts and for industrial manufacturing with a high throughput. The system is based on the proven EOS technology of the successful system EOS P 760 and offers improved part quality with a production volume of over 150 litres.

With the largest building volume available on the market, the EOS system permits the production of parts with lengths of up to one metre.

With 10 commercial polymer materials and 18 combinations of materials/layer thicknesses currently available, EOS is a benchmark in terms of material variety. In addition, the EOS ParameterEditor allows customized exposure parameters to be defined based on proven starting values.

The EOS P 770 system is ideal to manufacture large parts and high quantities of parts. Exemplary applications can be found in many areas. EOS itself, for instance, manufactures air ducts on the system, built in PA 2200 material. This serial part is installed into the EOS M 290 metal system.

Up to four of these large, functionally integrated air ducts can be manufactured in one build job. Compared to the predecessor system, the build time is reduced by good 20 percent.

GF Machining Solutions partner exhibitor at EOS booth

As part of their strategic partnership, EOS and GF Machining Solutions will be displaying the AM S 290 Tooling system at the EOS booth.

The Additive Manufacturing system for mould and die industry offers the proven quality of the Direct Metal Laser Sintering (DMLS) technology from EOS and enables the production of high-efficiency injection moulding tools with conformal cooling for serial production.

Additive Manufacturing technology allows companies to transcend conventional to conformal cooling and experience the thermal management benefits of conformal heating/cooling channels for plastic injection and die casting.

The solution ensures nearly unlimited freedom of design resulting in shorter cycle times, greater productivity, higher plastic product quality and lower energy consumption.

Together, GF Machining Solutions and EOS envision the integration of AM into the manufacturing process chain and are moving forward with a clear vision and a solution-oriented approach. GFMS’ tooling knowledge and EOS’ AM expertise are an ideal combination to provide a real benefit to our customers. With EOS as our strategic partner, AM technology becomes part of our portfolio to resolve customers’ manufacturing challenges.

Stefan Dahl, Head of Technology Unit New Technologies, GF Machining Solutions

About EOS

EOS is the global technology and quality leader for high-end solutions in the area of additive manufacturing (AM). The company, which was founded in 1989, is a pioneer and global leader in the area of direct metal laser sintering, and also a provider of a leading polymer technology. For these industrial 3D printing processes, EOS offers a modular solutions portfolio that consists of systems, software, materials, as well as technical and AM consulting services. EOS is the partner of choice for industrial AM-based production, and provides long-term solutions for industry. Customers using these solutions are able to take advantage of light-weight structures, cost reductions based on functional integration, product customization and accelerated product development and production. www.eos.info