The service life of China’s world leading high speed rail network has been successfully doubled with the application of electrical current collectors from Morgan Advanced Materials.

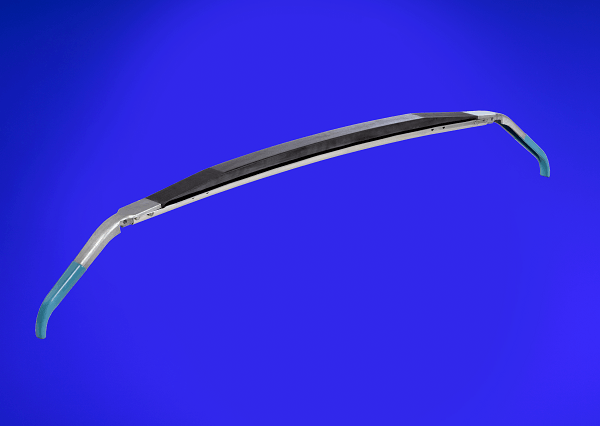

Morgan’s plain carbon strips and metallised collector strips have delivered a marked increase in service life when compared with alternative methods, and passed on a significant reduction in the operation and cost of the high-speed railway.

The products, which are in operation in China, now have potential to be used in a number of metro lines and high speed rail networks across the globe, delivering improved service life even during difficult weather conditions.

The strips offer a long-lasting alternative to the carbon traditionally used in rigid catenary systems, which is prone to wear from electric sparks and arcs, typically resulting in a limited service life.

Morgan’s products utilise a customised airway system within the carbon strip, which meets the demanding requirements of current collectors, with the right trigger sensitivity.

Self-supporting, the strips have been proven to reduce pan head mass and improve dynamic response, helping to lower the costs associated with operation and maintenance.

Similarly, because the products are specially engineered from Morgan’s advanced carbon material, they increase the service life of the carbon strip in high temperatures, dry conditions, and even the most challenging wet and humid environments.

This is of particular interest to China, which has the world’s longest high speed rail network. China’s network was used by approximately 1.1 billion people in 2015, making it the most heavily used in the world. For such a busy railway, high performance is critical, as any maintenance or downtime required on the track can lead to major disruption.

Morgan’s collector design has already gained approval by the EMU OEM of China Railway Rolling Stock Corporation (CRRC), as well as being certified by the China Railway Certification Centre.

The strips are a product of extensive research and development from Morgan, as it successfully developed a product with stronger electric wear resistance, even when the current capacity remains almost unchanged.

Every day a huge number of Electrical Multiple Units (EMUs) are running on a railway of 19,000 kilometres across China, covering various climates and geographical conditions. This poses challenges for the safety, reliability and on-time operation of the network, as well as driving up operation and maintenance costs. Our plain carbon and metallised collector strips leverage Morgan’s strengths in the material, design and application of current collectors and are poised to play a key role in improving the service life of high speed rail networks all over the world.

Boris Jaing, Managing Director of Morgan’s Electrical Carbon Business in Asia

For further information, please visit: www.morganelectricalmaterials.com/china-rail