Dec 8 2016

Materials innovator 3M has developed a 3D printing technology using fully fluorinated polymers. It said the technology is particularly exciting for PTFE (Polytetrafluoroethylene) applications and is aimed at the automotive, chemical processing, medical as well as energy and aerospace markets.

(Credit: http://www.materialsforengineering.co.uk/)

(Credit: http://www.materialsforengineering.co.uk/)

The process allows 3D printing as an additional and differentiated way of processing fully fluorinated polymers. It paves the way for the production of polymer structures in a single processing step rather than moulding and assembling component parts. Using this method, 3M is pioneering the 3D printing of PTFE that is used in a wide range of applications such as sealing and lining.

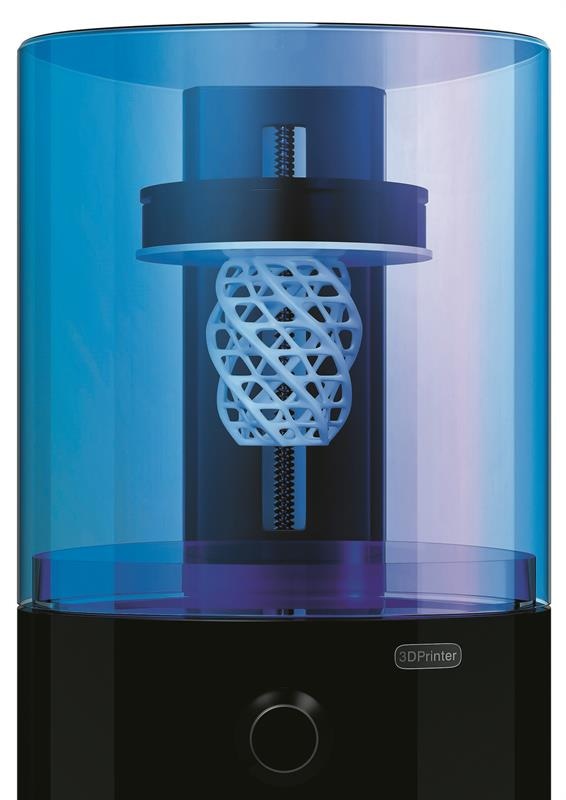

3M has selected stereolithography, also known as Vat Polymerisation, as the Additive Manufacturing process method for PTFE and other fully fluorinated polymers. The printed parts show similar physical properties to those produced using traditional processing techniques.

Stereolithography involves the curing or solidification of a photosensitive material using an irradiation light source. Typical tailor-made formulations used for 3D printing fully fluorinated polymers by stereolithography contain in addition to fully fluorinated polymers a binder and optional additives. The three processing steps required are aqua gel formation, drying and removal of the binder during heat treatment. This method can be used for PTFE compounds, too.