TMC, an industry leader in high-performance vibration isolation technology, introduces UltraDamp™, a very-high-damping pneumatic vibration isolation system that is ideal for vibration-sensitive applications with high-force, high- velocity X-Y motorized stages that require fast settling time of the payload.

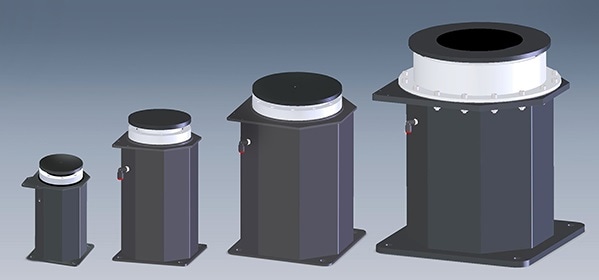

With UltraDamp, TMC expands its line of high-performance Micro-g® pneumatic vibration isolators, which offers a range of weight capacities, damping levels, and height control options for original equipment manufacturers’ (OEMs) in-tool applications.

Now, the tool designer can specify an isolator that exactly matches his needs by choosing the capacity, damping level and height control required. Isolators are available in a modular, interchangeable and upgradable design, making it easy to swap out isolators to accommodate changes in a tool’s requirements without a costly tool redesign.

Steve Ryan, Divisional Vice President for TMC

Isolator choices include three damping levels: Gimbal Piston™, MaxDamp® and UltraDamp – with maximum vibration attenuation or maximum damping. The isolators support payloads from 90 to 8,200 kg (200. to 18,000 lbs.) with three leveling performance options, offering standard height control valves, precision height control and TMC’s PEPS® II (Precision Electronic Positioning System).

Within TMC’s line of Micro-g isolators, its Gimbal Piston™ air isolators provide excellent vibration isolation with damping of payload disturbances. Some applications, however, require more damping. For those applications, TMC’s MaxDamp® isolators combine Gimbal Piston isolators with internal, tamper-proof viscous damping.

TMC’s new UltraDamp isolators offer an even more aggressive level of damping that ensures that the resonant frequency of the air isolators is not amplified by more than 3-5 dB. The UltraDamp is ideal for semiconductor, liquid crystal display (LCD) and photovoltaic cell (PVC) inspection and lithography tools as well as other instruments with motorized stages that require both vibration isolation and aggressive settling of payload-induced motion.