Digicom Electronics, Inc., a technology and quality driven electronics manufacturing services company based in Oakland, CA, will present methods for improving product quality and integrity during the electronics assembly process at the Design-2-Part Show, being held in the Santa Clara Convention Center, Santa Clara, CA, on May 24 and 25, 2017, in booth 331.

Improvement methods include Digicom's proprietary Diamond Track Nitrogen and Diamond Track Cleaning services to reduce or eliminate defects in printed circuit boards, especially for mission critical products such as those used in the medical, military and aerospace, industrial, and RF wireless industries.

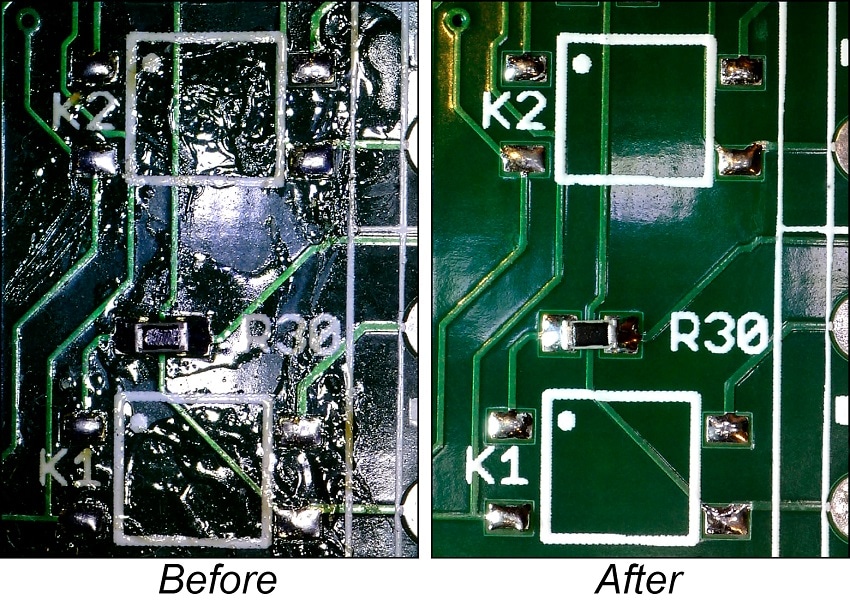

Digicom's nitrogen initiative generates nitrogen for use during the solder reflow, selective soldering, and hand soldering processes to strengthen solder bonds and improve solder adhesion. Adding nitrogen minimizes device failures and ensures printed circuit board integrity. Digicom's Diamond Track Cleaning process is the result of years of research and experimentation, and has been proven to deliver significantly better than the IPC's ionic cleanliness guidelines' allowable level of contamination.

"A company's product quality, reliability, and reputation are often shaped by the contract manufacturer that company uses. Digicom's nitrogen generation and integration and cleaning services are two of the methods we employ to mitigate failure and produce success. Learn about others by stopping by our booth at the Design-2-Part Show, visiting our newly expanded facilities in Oakland, CA in the San Francisco Bay area, or contact me at +1-510-639-7003, email [email protected]," said Mo Ohady, general manager for Digicom Electronics.

Digicom helps companies with their complete process from design review through prototyping, component sourcing, manufacture, test, and process validation. Digicom is certified for ISO 9001:2008, ISO 13485:2003 medical devices quality, quality system regulation 21 CFR 820, and ITAR certification. AS9100 aerospace certification will be completed in June. See our videos, articles, and information at www.digicom.org