Nov 15 2017

High-efficiency electric motors with custom-made speed-torques, defined by their magnetic components, are vital for sustainable, effective electric automobile drive concepts.

Soft magnetic core engineering plays a crucial role in these motors, where the chief soft magnetic materials used presently are electrical steels. But for higher-frequency applications, soft magnetic composites (SMCs) are also favorable candidates.

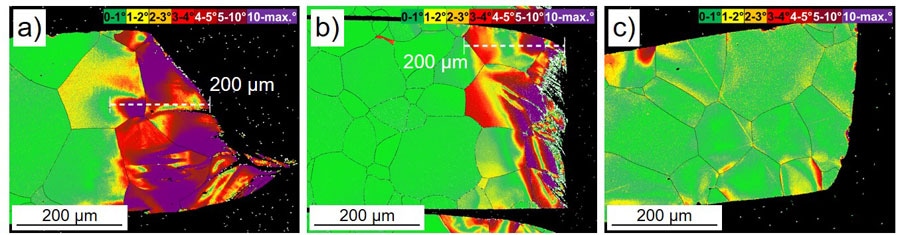

Comparison of the influence of different cutting methods on the deformation of the edge of electrical steel sheets: a) rough cutting using a blunt object, b) industrial punching tool and c) laser cutting. (CREDIT: Image courtesy of the authors)

Comparison of the influence of different cutting methods on the deformation of the edge of electrical steel sheets: a) rough cutting using a blunt object, b) industrial punching tool and c) laser cutting. (CREDIT: Image courtesy of the authors)

Each of the various stages of motor construction, such as rolling, laser cutting, punching or annealing, influences the material’s microstructure and can result in magnetic losses. Understanding the details of the microstructure is vital to attaining higher efficiency for electrical motors. As a result of the high rotational speed of traction drives, over 5% of the electric energy created is lost as heat.

In a paper published recently in the journal AIP Advances, from AIP Publishing, researchers at the University of Aalen in Germany developed an advanced characterization technique to thoroughly examine microscale structural features and variations during manufacturing processes using electron backscatter diffraction (EBSD).

When you have deformations from machining, it is a great help to make the deformations visible. In order to get deeper insight into the material’s structure, electron backscatter diffraction is really useful. For example, grain size and shape, texture and degree of elastic strains and plastic deformations can be determined.

Dagmar Goll, Author and Professor of Physics of Magnetic Materials, Aalen University

The researchers compared the effects of a range of machining types on the microstructure of electrical steel. During machining, the material’s cutting edge is damaged, altering the crystallographic structure. “We evaluated the misorientations of grains in the material. So in the case of the cutting edge, we evaluated inhomogeneous areas with plastic deformations,” Goll said. While these features are microscopic, the cumulative effect in the material’s structure totals up to a loss of efficiency in the final product.

“In the case of the powder metallurgical soft magnetic composites, which allow a higher degree of freedom in the design and construction of electric motors, we evaluated the recrystallization process during manufacturing as a function of compaction pressure, annealing parameters and powder particle size,” author David Schuller said.

We are improving the ratio between particle size and grain size distribution of the material. Depending on the annealing temperature, we can control grain growth and recrystallization in order to tailor the magnetic properties and minimize the magnetic losses.

David Schuller, Author

The methodology created by Schuller and colleagues provides a new tool to see precisely where, how, and to what extent the crystalline structure is disturbed in machining processes and can be recovered during annealing. Their results reveal that EBSD is a robust and versatile characterization method for examining and customizing soft magnetic materials.