In the world of AI and ever-growing complexity, sometimes “less really can be more.” This phrase often holds true with sensors and sensing solutions.

There are always occasions when you need to generate and work with dense point clouds, but there are many other times when a more thoughtful application of sensors can be a leaner and more reliable solution.

Image credit: Terabee

Image credit: Terabee

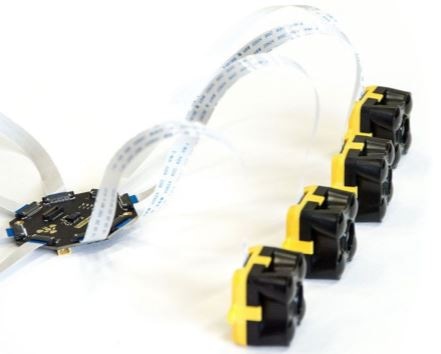

Terabee - creators of the TeraRanger Time of Flight distance sensor - has just released a new generation plug and play solution for using multiple distance sensors. The TeraRanger Hub Evo is a small, octagonal PCB, which allows you to connect up to eight TeraRanger Evo distance sensors and place them in whatever configuration you might need.

In this way, you can monitor and gather data from the areas and axes you need and create custom point clouds, optimized for your application. The Hub provides power to each sensor, prevents sensor crosstalk, synchronizes the data and outputs an array of calibrated distance values in millimeters. It also has a built-in IMU.

We’ve been advocating the use of ‘selective point clouds’ for a while. It’s a concept we’ve presented at a number of conferences, including the Intelligent Robots and Systems conference (IROS) and Vision.

We understand that people often feel more secure by gathering millions of data points, but let’s not forget that every point gathered needs to be processed. This typically requires complex algorithms and lots of computing power, relying heavily on machine learning and AI as the system grows in complexity. And as things become more complex, the computational demands of the system rise and the potential for hidden failure modes also increases. Taking the mechanical engineering approach - trying to solve the problem in the easiest way possible ‘lean-sensing’ could well be a less complex, lower cost and more reliable solution in many applications.

Max Ruffo, CEO of Terabee

In this example, Terabee showcases lean-sensing and selective point cloud creation on a large mobile robot used for wrapping pallets with a thin film. In the real-world of logistics, pallets are often piled with objects of random shapes, and sometimes these can overhang the edges of the pallet.

Max explains, “Our customer needed a contactless method for their robot to rotate around a pallet of goods at high speed (up to 1.3 meters per second) to apply thin film pallet wrap. As well as being fast, the system needed to be computationally lean (to ensure robustness) and also cost-effective.”

The solution Terabee designed uses just sixteen single-point distance sensors, operating as small arrays, to generate selective point clouds. Three sensors look to the side to maintain a safe and consistent distance to the pallet, while five sensors look forwards to provide collision avoidance and safety should something, or someone, enter the path of the robot.

Another array, this time eight sensors, faces the area where pallet contents are. This array builds, in real-time, a lean point cloud of the pallet contents, including any irregularities such as overhangs. This three-dimensional data is then fed to the control system so that the two-dimensional trajectory of the robot can be adapted to ensure the robot avoids any overhanging items and optimizes its path for pallet wrapping.

Just sixteen numbers (plus some minor data from wheel odometry and the IMU) are fed to the control system, enabling three-dimensional data points to change the two-dimensional trajectory of the robot, in real time, at high speed. It’s incredibly simple, computationally light, reliable and robust.

Max comments, “The solution could probably run just as well with fewer sensors and we are now testing to see how few sensors can be used without compromising performance, reliability or safety.”

All this is possible because of the TeraRanger Hub Evo and its simple plug and play capabilities. By using the small, lightweight and high-performance TeraRanger Evo distance sensors, sensors can be placed in all kinds of places and in just about any configuration needed.

We’ll continue to develop our Hub and multi-sensor concept, making it easy for people to use our sensors in configurations to meet their specific needs. It’s already proven to be a very popular way for people to prototype and use multiple sensors for drones, robotics, industrial applications and more recently some smart city use cases too.

Max Ruffo, CEO of Terabee

Request a quote for the TeraRanger Hub Evo

Request a quote for the TeraRanger Hub Evo