Apr 24 2018

Researchers at Brown University have developed a novel theory to explain how the performance of metal catalysts can be improved by stretching or compressing them. Illustrated in the journal Nature Catalysis, the theory could pave the way for unique design possibilities for new catalysts with new abilities.

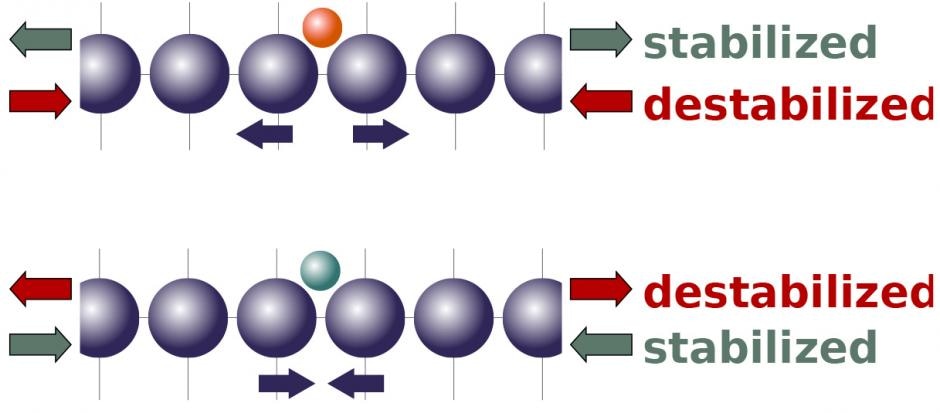

Push and pull. Brown University researchers have shown that the effects of external strain on a catalyst depend on the internal strain exerted by chemical reactants. That new theoretical framework could be useful in optimizing catalysts for different reactions. (Image credit: Peterson lab / Brown University)

Push and pull. Brown University researchers have shown that the effects of external strain on a catalyst depend on the internal strain exerted by chemical reactants. That new theoretical framework could be useful in optimizing catalysts for different reactions. (Image credit: Peterson lab / Brown University)

Catalysts are basically substances that accelerate chemical reactions. Most of the industrial catalysis involves solid surfaces—usually metals—that catalyze reactions in gases or liquids. For instance, a catalytic converter on a car employs metal catalysts to remove toxins from exhaust fumes. Metal catalysts are also increasingly being used to change carbon dioxide into fuels, drive reactions in fuel-cell cars, and make fertilizers from atmospheric nitrogen.

In recent years, research has demonstrated that when a strain is applied to metal catalysts—either tension or compression—it can change the way they perform in certain cases.

Strain is a really hot topic in catalysis right now. We’ve starting seeing things happening under strain that aren’t easily explained by the traditional theory of how catalysts work. That got us thinking about an alternative framework for this question.

Andrew Peterson, Co-Author & Assistant Professor - Brown’s School of Engineering

A metal catalyst operates by making the reactants to adhere to its surface. This process is referred to as adsorption. During adsorption, chemical bonds of the reactant molecules break down, allowing different stages of a chemical reaction to occur on the surface of the metal. Once the reaction stages are over, the end product is discharged from the catalyst via the reverse process, known as desorption.

Reactivity is the main property of a catalyst—that is, how tightly it holds chemical molecules to its surface. For binding to take place, catalysts have to be slightly reactive but not overly reactive. If there is excess reactivity, it can cause the catalyst to bind molecules too tightly, which can obstruct some stages of the chemical reaction or make it such that the end products are unable to desorb.

Recently, it has been demonstrated that when a strain is applied to a catalyst, it can adjust its reactivity, and there is a well-established theory to show how it works. On the whole, the theory predicts that compression strain should reduce reactivity, while tensile strain should increase it. Yet, Peterson and his team continue to encounter systems, which the theory could not explain easily.

That prompted the team to think new means to assess the problem. The conventional theory elucidates things on the level of electron bands and electrons. However, the latest theory zooms out a bit, concentrating instead on the technicalities of how molecules interact with the atomic lattice of a catalyst.

Peterson and his group demonstrated that molecules binding to the surface of a catalyst will tend to either pull atoms closer together or push them in the lattice apart, based on the characteristics the binding sites and the molecules. Molecules produce varying forces, which have interesting implications for how external strain should influence the reactivity of a catalyst. It indicates that tension, which stretches the atomic lattice of a catalyst, should increase the reactivity of a catalyst for molecules that apparently want to push the lattice apart and simultaneously, it should make the catalyst less reactive to molecules that want to pull the lattice together. Squeezing the lattice or compression has an opposite effect.

The latest theory not only helps in explaining the previously perplexing results but also aids in making new, significant predictions. In particular, it predicts a means to break conventional scaling associations between catalysts and various types of molecules.

Scaling relations mean that, under normal circumstances, when you increase a catalyst’s reactivity for one chemical, it increases the reactivity for other chemicals as well. Similarly, if you decrease reactivity for one chemical, you decrease it for others.

Andrew Peterson, Co-Author & Assistant Professor - Brown’s School of Engineering

However, troublesome tradeoffs are caused by those scaling relations when attempting to improve a catalyst. Achieving the perfect reactivity for one chemical can make another chemical to adhere too loosely or too tightly, possibly preventing some stages of a chemical reaction to take place. However, this novel theory indicates that those scaling relations can be broken down by strain, allowing a catalyst to bind one chemical more loosely and another more tightly simultaneously, based on the natural interaction of the chemical with the atomic lattice of the catalyst and the way that the strain field is designed on the surface of the catalyst.

Now you can start to think about really fine tuning catalysts to perform better throughout different reaction steps. That could dramatically improve a catalyst’s performance, depending on the chemicals involved.

Andrew Peterson, Co-Author & Assistant Professor - Brown’s School of Engineering

A database of standard reaction chemicals as well their interactions with various catalyst surfaces is being peppered by Peterson’s team. That database can possibly act as a guide for locating reactions that could gain from strain and the breaking of scaling relations.

Meanwhile, Peterson believes that the work completed by his team so far will offer the catalysis community with a new means of thinking about strain.

“We’re trying to give a framework that provides a more intuitive understanding how strain works in catalysis,” Peterson said. “So as people design new catalysts, they can think of ways to better harness these strain effects.”

The U.S. Army Research Office (W911NF-11-10353) supported the research. Alireza Khorshidi, James Violet, and Javad Hashemi were other authors on the paper.