Aug 16 2018

It has become commonplace to tune materials to achieve ideal electrical and optical properties. Presently, scientists and manufacturers may be able to alter materials for thermal conductivity by using a squid-inspired protein composed of multiple DNA repeats.

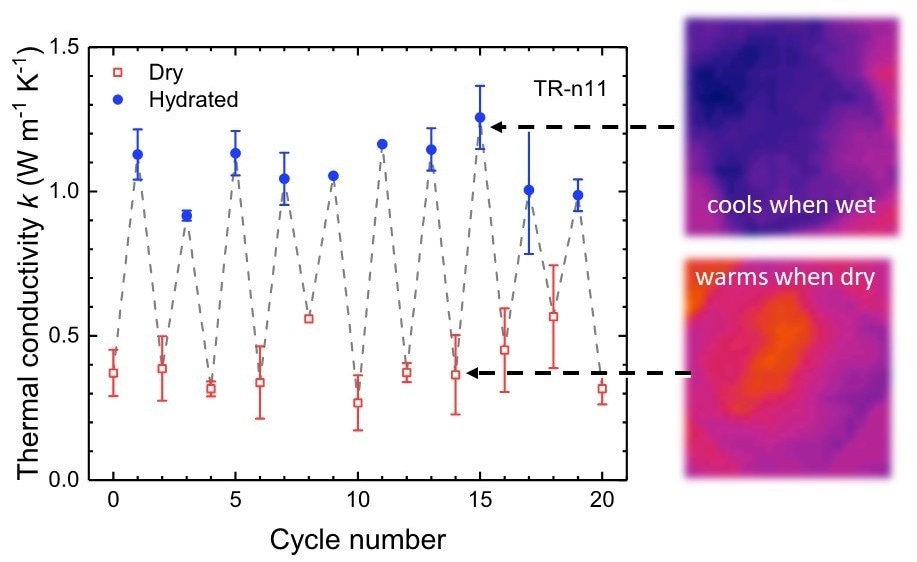

Graph showing cycles of thermal conductivity when material is wet and then dry. (Image credit: Melik Demirel)

Graph showing cycles of thermal conductivity when material is wet and then dry. (Image credit: Melik Demirel)

Controlling thermal transport in modern technologies - refrigeration, data storage, electronics or textiles - is an unsolved problem. For example, most standard plastic materials have very low thermal conductivity and they are thermal insulators. These squid-based bio-materials that we are working on have low conductivity at ambient humidity, but they can be engineered so that their thermal conductivity increases dramatically.

Melik Demirel, Professor of Engineering Science & Mechanics at Penn State

In this case, the increase is reliant on the number of tandem repeats in the protein, and can be 4.5 times larger than increases observed in conventional plastics. Tandem repeats are repeating strings of DNA that originate in nature, in this case, in squid ring teeth.

One probable use of this bioprotein film might be as a fabric coating, particularly for athletic wear, said the scientists. The material could be impeccably comfortable and cozy in routine use, but when essentially used for heavy activity, the sweat produced by the wearer could “flip” the thermal switch and allow the fabric to eliminate heat from the wearer’s body.

Demirel and his team have engineered synthetic proteins that are patterned on tandem repeating sequences. They are able to select the number of repeats they require and examine how the different proteins react, in this experiment, to moisture.

"Under ambient conditions - less than 35 percent humidity - the thermal conductivity of these proteinaceous films do not depend on repeat units or molecular weight, and demonstrate similar thermal conductivities to disordered polymers and water-insoluble proteins," the scientists reported on August 13th in Nature Nanotechnology.

However, when the films are designed to possess higher molecular topology, the thermal conductivity increases when they become wetter, through water, high humidity, or sweat. In partnership with the University of Virginia team and NIST, the scientists discovered that as the number of tandem repeats grew, the thermal conductivity also increased.

Because the thermal conductivity when wet is linearly related to the number of repeats, we can program the amount of thermal conductivity into the material. So, we could make better thermal switches, regulators and diodes similar to high-performance devices to solve the problems in modern technologies such as refrigeration, data storage, electronics or textiles.

Melik Demirel, Professor of Engineering Science & Mechanics at Penn State

When the material comes back to standard ambient humidity or lower, the switch turns off, and the protein does not conduct heat as efficiently.

Other Penn State scientists involved in this study are Abdon Pena-Francesch, recent Penn State doctoral recipient and now a von Humboldt Fellow at the Max Planck Institute, Stuttgart, Germany; Huihun Jung, doctoral candidate in engineering science and mechanics; and Benjamin D. Allen, assistant research professor of biochemistry and molecular biology.

Other researchers are John Tomko, graduate student in materials science and engineering, University of Virginia; Patrick E. Hopkins, associate professor of mechanical and aerospace engineering, engineering science and mechanics and physics, University of Virginia; and Madhusudan Tyagi, assistant research scientist, National Institute for Standards and Technology.

Neutron-scattering experiments were done at NIST, Center for Neutron Research. The Office of Naval Research, the Army Research Office and Penn State’s Materials Research Institute aided this research.