Bruker Nano Surfaces today announced a partnership with Greening Testing Laboratories, Inc. of Detroit to provide convenient and cost-effective benchtop friction test and particle screening capabilities to developers of friction materials. Under this partnership, Greening will leverage Bruker’s latest generation TriboLab Brake Material Screening Tester for measurement services, as well as for the evaluation of the tester for potential purchase.

“We are excited to continue working with Bruker to offer testing and measurement services to the auto industry,” said Charles W. Greening, Jr., President of Greening, a leading provider of custom-engineered dynamometers and friction material test equipment. “The UMT TriboLab has proven capable of generating useful data that correlates well with full-scale dynamometer tests. We plan to offer in-house benchtop testing and/or evaluation for purchase by the end of summer.”

James Earle, Vice President and General Manager of Bruker’s Tribology, Stylus and Optical Metrology Business added: “Building on the success of the TriboLab platform, Bruker is pleased to partner with Greening to provide automotive engineering and manufacturing firms a turn-key screening solution to reduce the cost of new materials development and to aid compliance with changing regulations.”

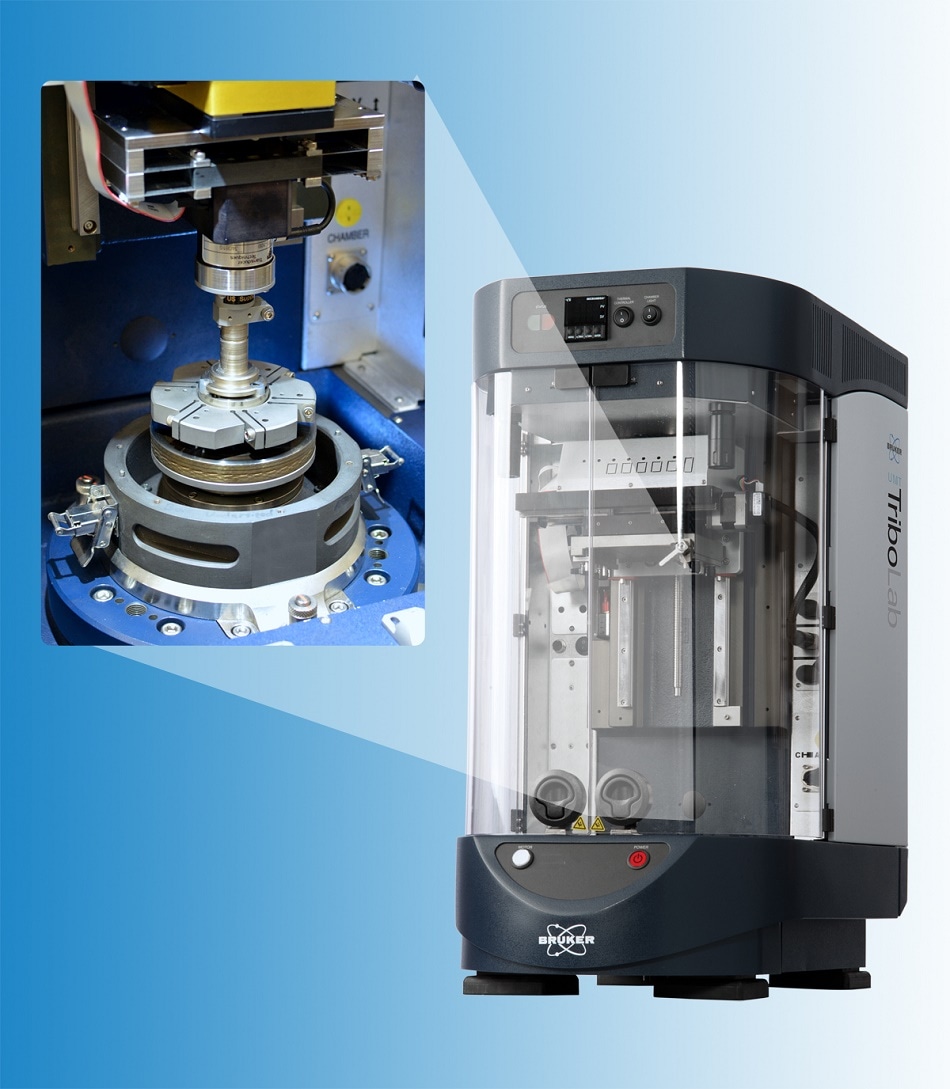

About TriboLab Materials Screening Tester

Built upon Bruker’s industry-leading UMT TriboLab platform, the new tester enables fully scaled friction measurements at different speeds, deceleration times, and temperatures, applying the comparable contact pressures used in a full-scale dynamometer rig. The flexibility and range of testing capabilities of the TriboLab Brake Material Screening solution rapidly and cost-effectively allows users to rank materials using protocols based on industry standards such as the SAE J2522 (AK Master).