Nov 5 2018

Polyurethane foams are usually used for making mattresses, car seats, and insulation materials. The foaming process for the liquid polymer emulsions is complicated. Currently, Fraunhofer scientists have been successful in simulating the foaming behavior and reliably characterizing the material. This also holds good for composite materials in which the plastic foams are integrated with textile structures.

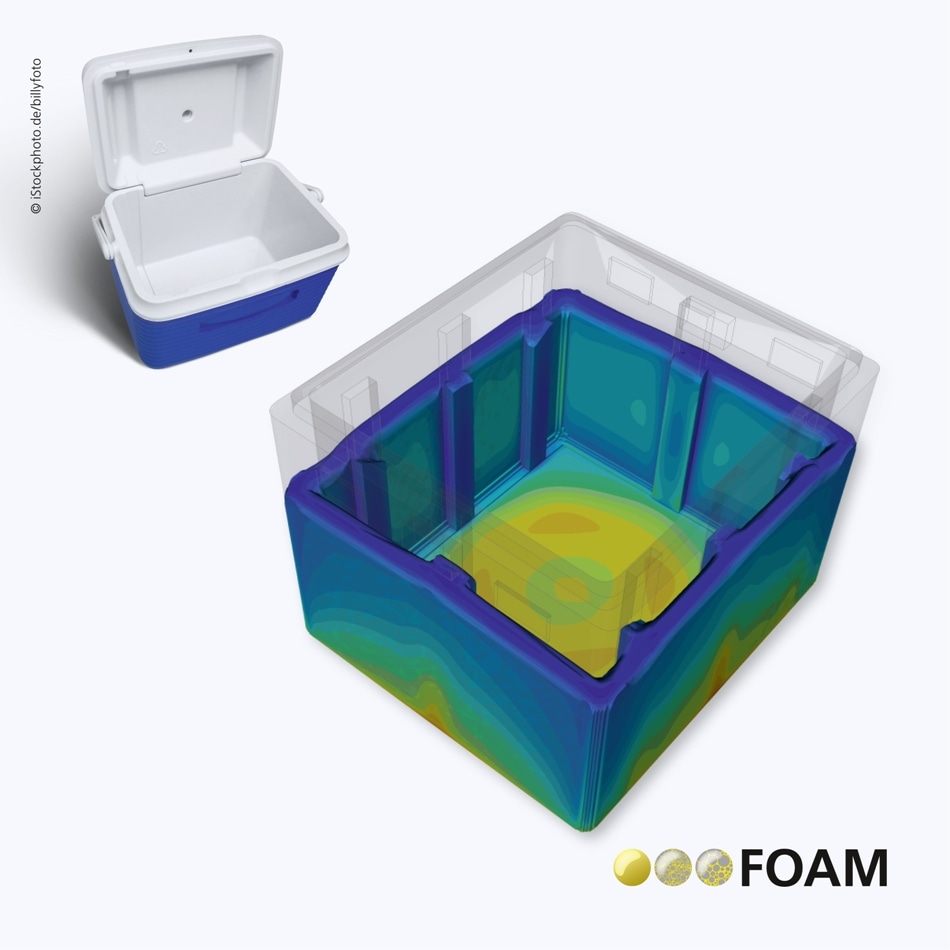

PU expansion simulation with FOAM for manufacturing a cooler. (Image credit: Fraunhofer ITWM)

PU expansion simulation with FOAM for manufacturing a cooler. (Image credit: Fraunhofer ITWM)

Polyurethane foams, or PU foams, have a vital role in the day-to-day lives of people, although people are usually not aware of them. Every day, people sit and lie on them: for instance, mattresses and car seats are made of soft PU foams. In contrast, hard PU foams are used, apart from other things, as insulation materials in buildings. It is highly complicated to predict the properties of foams and characterize them—experimental investigations usually result in false parameters.

Better planning of new product lines

The following questions are of specific interest: How does the initial liquid transform into foam? And what are the properties of the created foam? At present, scientists from the Fraunhofer Institute for Industrial Mathematics ITWM in Kaiserslautern are in a position to reliably answer these questions and offer PU foam products manufacturers with an optimal characterization of the polymers used, rendering it considerably easier for them to plan new product lines. This can be explained in the best possible way with an example, such as a car seat. In this case, certain areas are intended to be harder and others softer.

Manufacturers accomplish this by injecting foams with different properties against each other. Liquid polymer blends are used as starting materials, which are injected into an appropriate mold: a fast but complex chemical process starts. In just a few seconds, the two liquid emulsions change into a complex polymer foam. However, precisely in what way do the two different substances foam? Do they have the needed characteristics, and do they spread as intended into their proper zones?

Instead of starting with chemistry and experimentally determining all parameters such as reaction rates and viscosity in many independent experiments, we do two or three simple experiments—such as foaming in beakers. We simulate these experiments one to one on the computer. These experiments serve to establish the model parameters needed for the FOAM simulation tool, which calculates foaming behavior based on simulations. The results are robust and reliable for the specific application.

Dr. Konrad Steiner, Head of Department, Fraunhofer ITWM.

Rather of separately determining each characterizing parameter in an individual experiment, which could result in imprecise values, scientists can now rapidly acquire reliable data for the foaming process with lesser effort.

“Manufacturers usually work with three or four different foams—for new products, they generally just change the combination of foams and the end geometries,” stated Steiner. As soon as the Fraunhofer scientists characterize a PU foam by means of simulation, this serves as a good starting point for innovative products. The foam data received by the manufacturers can be input by them into the FOAM simulation tool and simulations can be performed for each new product and each new geometry according to the way in which the foam mass and heat should be transported during the foaming process. In the case of a car seat, they can discover precise ways to inject the two foams against each other to accomplish the desired zone properties at the right places.

The simulation methodology for recognizing parameters and simulating foam with the FOAM tool has been established, and various projects are already underway with a number of customers.

Composite materials with PU foams

Manufacturers usually depend on PU foams in composite materials, for instance, those used for support structures in cars, which have to be stable but lightweight. In this case, other reinforcing materials like textiles are combined into the foams. While a rigid foam sheet is prone to breakage upon being forced to bend, a sheet with combined textiles can easily endure these forces. However, the flow behavior of the polymer emulsion varies when the textile structure in the mold naturally acts against this, resulting in variations in the dynamics of foam formation and the structure of the foam: the bubbles turn smaller, and the foam gets denser.

The researchers at Fraunhofer ITWM, in collaboration with colleagues from the Department of Lightweight Structures and Polymer Technology at TU Chemnitz, have created the first-ever simulation for composite materials.

We are able to calculate the flow resistance caused by the corresponding textile structure, which is an expertise that we have possessed for some time now. Subsequently, we can simulate how foaming takes place in and around the textile structure.

Dr. Konrad Steiner, Head of Department, Fraunhofer ITWM.

Earlier, manufacturers had to strenuously test whether the foam composite had the needed characteristics—a process that could take weeks or even months. On the contrary, the simulation gives a reliable result within one or two days. The researchers have already validated and investigated the results on components and established that they match up very well with reality.